Web Design And Seo For www.china-webdesign.com

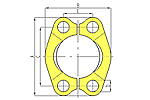

hydraulic flanges - China Manufacturer

Thank you for inquiry my hydraulic flanges, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/Flange-Fitting/

(1) processing to remove all parts of the burr to prevent glitches in the operation is washed fall into the working oil.

(2) assembly carefully cleaned the tank, pump housing, conduit casing, rotary components, to prevent debris f rom entering the box.

(3) To pipeline installation of pipelines clean, try to rinse and then install the welding, to prevent oxide into the oil.hydraulic cutting machine

(4) Prior to commissioning, the variable speed hydraulic coupling should use filter cleaning pipes, cleaning after oil filters clean.

(5) constant filling fluid coupling first run 500h, replaced with new oil, oil change, cleaning the coupling cavity.

(6) whether the failure at any time to check the air filter, and replaced with qualified products.

(7) Regular cleaning oil pump suction port of the oil filter, remove dirt, to prevent the flow rate decreases.hydraulic machines

(8) a reasonable choice of filters, specifications and reasonable arrangements for its location. Rated flow of the oil filter should gen erally be greater than the rated flow of working oil pump 3 to 5 times, thus reducing the pressure loss and the number of filter replacement, oil filter can improve function.

(9) The oil temperature should be controlled below 70 ℃ should be cause for the oil temperature is higher oily aging.hydraulic manifolds

(10) the use of qualified hydraulic transmission oil. To see the oil change, oil quality is qualified with impurities, moisture.

没有评论:

发表评论