We are engaged in providing a range of high pressure hydraulic hose assembly which uses high-quality synthetic inner, outer cover, has a good stretch silk and rayon made of steel. These single wire braided hydraulic hose ideal for use in various industries, including automotive, industrial, medical and aerospace industries. This is considered an effective way to convey a fluid under pressure.

As a result of high tensile steel wire, single wire braided hydraulic hose is workable to support specified working pressure. For this reason, it is not necessary to employ double wire braid hose. However, when the working environments are abrasive and corrosive, two braided hydraulic hose is a better alternative. The extra braid protects interior rubber and greatly extends hose service life.

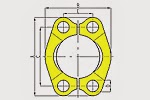

parher wire braided hydraulic hose with power steering pump assembly is the main function of the work piece, the assembly consists of four parts assembly components.

2015年12月27日星期日

2015年12月22日星期二

Hydraulic Hose better knowledge

Ningbo PH Machinery Factory Co., Ltd. Parher has grown up into a leading hydraulic hose machine in China. With the continuous economic development, hydraulic hoses have been extensively used in industries, mines, steel works and chemical factories. Compared to rigid pipes, hydraulic rubber hose can bend to specified radius and resist vibration damage.

Our factory has introduced advanced hose making machinery and production process to improve hose quality and satisfy customer's stringent requirements. In recent years, we've exported to many countries including America, Britain, France, German, East Asia and other countries.

Our factory has introduced advanced hose making machinery and production process to improve hose quality and satisfy customer's stringent requirements. In recent years, we've exported to many countries including America, Britain, France, German, East Asia and other countries.

2015年12月17日星期四

Adout single wire braid hose safety

When the One wire ferrule cannot provide a measure of safety then a second layer of wire braiding is added. And there are two reasons to consider for this: the extra wire provides for higher working pressure, and the interior braid is still protected if the hose cover has been damaged and the exterior braid may rust and fail. This is an important consideration where hoses are subject to external damage and then left out in the weather (for example the farm machinery). Double wire braided hydraulic hose is widely used in the daily life and industry because of its features of moderate price, large scope of applications and providing of a measure of safety.

2015年12月12日星期六

wire braided hydraulic hose can be divided into many types

wire braided hydraulic hose can be divided into many types according to the layer number. Here we will introduce two kinds of wire braid hydraulic hoses that are widely used in the markets. They are namely single wire braid hose and double wire braided hose.

Steel wire braided hoses can be used to transport petrochemicals and hydraulic fluids under relatively high pressures and temperatures. In addition, oil-resistant wire braided hoses can provide flexible connections between steel pipes in hydraulic machines systems. They can find their applications in the fields of mine hydraulic bracket, automatic hydraulic systems of oil field exploiting machine, mine projects and other industrial sectors, especially used as jackhammer component. It can withstand in the temperature of -40°C to +100°C, and the maximum temperature can be +125°C. Also the surface of steel wire braided hydraulic hose can be two types including smooth and fabric surface.

Steel wire braided hoses can be used to transport petrochemicals and hydraulic fluids under relatively high pressures and temperatures. In addition, oil-resistant wire braided hoses can provide flexible connections between steel pipes in hydraulic machines systems. They can find their applications in the fields of mine hydraulic bracket, automatic hydraulic systems of oil field exploiting machine, mine projects and other industrial sectors, especially used as jackhammer component. It can withstand in the temperature of -40°C to +100°C, and the maximum temperature can be +125°C. Also the surface of steel wire braided hydraulic hose can be two types including smooth and fabric surface.

2015年12月7日星期一

Hydraulic adaptors (hydraulic pressure allocator)

Hydraulic adaptors (hydraulic pressure allocator) is widely used in engineering machinery, agricultural machinery, hydraulic system control, mainly by the control valve opens and closes to control the flow of hydraulic fluid to control

the direction of the hydraulic cylinder mechanical action.The main sub-manual control, electric control and pressure control and other types. Most of the domestic agricultural manual control and mechanical control distributor, imported mostly large-scale agricultural and excavators electric control distributor.

American hose fittings is manually distributor of automotive control valve.

2015年12月2日星期三

Future british hydraulic fittings

So saves time in the cutting process, greatly improve the production efficiency. Future british hydraulic fittings should provide full automation development, with pipe cutting counting function, automatic loading and unloading, the length by computer control, set up after a good program to automatically cut to length, so we make hose assembly will greatly reduce the cost I hope hydraulic ferrule fittings devised a more perfect hose cutter.

2015年11月27日星期五

Hose Storage

(1) Storage warehouse hose should be kept clean, ventilation, relative humidity below 80%, the temperature inside the warehouse should be kept between -15 ~ + 40 ° C, and avoid direct sunlight and rain and snow hose dip shower.

(2) when the hose storage, should be placed under the different varieties and specifications are not mixed stack, and to obtain access badges.

(3)hydraulic hose stored in a relaxed state as possible, generally less than 76mm inside diameter hoses coiled storage (but not less than the inner diameter of the disk 15 times the inside diameter of the hose)

(4) In order to prevent the hose storage tube compression deformation, stacking is not too high, generally stack height should not exceed 1.5m; and require the c during storage is often "down stack", generally at least once every quarter .

Heat from the outside and should be away from 1m; (5) the hose storage, not acid, alkali, oils and organic solvents or other corrosive liquids, gases in contact with

(6)hose fittings during storage, non-stacked tubular body weight and prevent outside squeezed and damaged.

(7) hose during storage generally should not exceed two years, and should be used before storage, first use, to prevent prolonged storage affect the quality of the hose.

2015年11月24日星期二

Hose transportation

hydraulic hose during loading and unloading, should pay attention to the following points

hose fittings during loading and unloading, to do Handle gently.

Hose reel need Classification (article) neat shipment, to avoid excessive bending of the tube discounts, and should not be on the heap pressure hose other heavy objects.

Prohibited the hose with acids, alkalis, oils and organic solvents, flammable and explosive materials mixed; tube should not be in direct contact with the sharp edge of the cargo.

For straight transport hose required when length exceeds the load compartment, the long part should support bracket to prevent damage to the hose on the ground mop.

If for any reason need to hose temporarily parked in the open air (or workshop Pier), the site must be flat, flat hose should be neat, and do underlay cover, do not stack ballast; at the same time, the hose is not in contact with the heat source.

When transporting hose should not drag anywhere on the heavy hose lifting equipment should be used special equipment or handling and to prevent the hose from accidental damage.

2015年11月19日星期四

Hydraulic working medium

Acting hydraulic machines used for working medium not only to pass the pressure, but also to ensure the machine working parts work is sensitive, reliable, long life and low leakage. Hydraulic basic requirements for working medium are: ① have appropriate liquidity and low compressibility in order to improve the efficiency of the transmission; ② can prevent corrosion; ③ good lubricating properties; ④ easy to seal; ⑤ stable performance, long-term work without deterioration. hydraulic machines with water as the working medium initially, after the switch in water by adding a small amount of emulsified oil emulsion made to increase lubricity and reduce corrosion. Late appeared to mineral oil as the working medium of the hydraulic machine of the 19th century. Oil has good lubricity, corrosion resistance and moderate viscosity, help to improve the performance of hydraulic machines. The second half of the 20th century there has been a new type of water-based emulsion, which emulsion form is "water in oil" instead of the original "oil in water." "Water in oil" emulsion external phase is oil, its lubricity and corrosion resistance close to the oil, and a small amount of oil, non-flammable. But the water-based emulsion expensive, limiting its promotion.

2015年11月11日星期三

Hydraulic Works

hydraulic machines used for working medium not only to pass the pressure, but also to ensure the machine working parts work is sensitive, reliable, long life and low leakage. Hydraulic basic requirements for working medium are: ① have appropriate liquidity and low compressibility in order to improve the efficiency of the transmission; ② can prevent corrosion; ③ good lubricating properties; ④ easy to seal; ⑤ stable performance, long-term work without deterioration. Hydraulic machine with water as the working medium initially, after the switch in water by adding a small amount of emulsified oil emulsion made to increase lubricity and reduce corrosion. Late appeared to mineral oil as the working medium of the hydraulic machine of the 19th century. Oil has good lubricity, corrosion resistance and moderate viscosity, help to improve the performance of hydraulic machines The second half of the 20th century there has been a new type of water-based emulsion, which emulsion form is "water in oil" instead of the original "oil in water." "Water in oil" emulsion external phase is oil, its lubricity and corrosion resistance close to the oil, and a small amount of oil, non-flammable. But the water-based emulsion expensive,

2015年11月9日星期一

hydraulic fittings manufacturers good news is

This construction machinery industry, the most prominent contradictions finally attracted much attention, the huge market demand has finally push the industry forward fittings rolling wheels. October 11, 2010, bspt fittings the Ministry of Industry and Information Technology issued "basis machinery parts industry revitalization plan." Which clearly should be made to accelerate the pace of development of key components to break the bottleneck, we continue to meet the needs of the field equipment and the development of strategic emerging industries.British hydraulic fittings good news is, this construction machinery industry, metric tube fittings the most prominent contradictions finally attracted much attention, the huge market demand has finally push the industry forward fittings rolling wheels. October 11, 2010, the Ministry of Industry and Information Technology issued "basis machinery parts industry revitalization plan."

2015年10月31日星期六

Parher wire braided hydraulic hose precautions for use

Parher wire braided hydraulic hose precautions for use:

1, the bending radius should not be less than a given bend radius to prevent damage due to excessive stretching or hose skeleton, early damage.

2, according to the conditions, the correct selection of hose varieties, specifications, do not misuse or substitute.

3, use the wire spiral hose, the pressure should be balanced slowly adjusted to avoid a sudden pressure increase damage to the tube.

4, when the change of duty station, ground handling should not be mopping the floor, so as not to scratch the outer plastic, corrosion skeleton layer.

5, transporting corrosive liquids inside should be cleaned after use to prevent corrosion residue long tube, or choose the appropriate products.

1, the bending radius should not be less than a given bend radius to prevent damage due to excessive stretching or hose skeleton, early damage.

2, according to the conditions, the correct selection of hose varieties, specifications, do not misuse or substitute.

3, use the wire spiral hose, the pressure should be balanced slowly adjusted to avoid a sudden pressure increase damage to the tube.

4, when the change of duty station, ground handling should not be mopping the floor, so as not to scratch the outer plastic, corrosion skeleton layer.

5, transporting corrosive liquids inside should be cleaned after use to prevent corrosion residue long tube, or choose the appropriate products.

2015年10月26日星期一

Parher wire braided hydraulic hose features

Parher wire braided hydraulic hose features:

1, Hose special selection made with synthetic rubber, has excellent oil resistance, heat aging resistance.

2, hose bearing pressure, pulse superior performance.

3, tube linked closely together, use a soft, small deformation under pressure.

4. Hose has an excellent resistance around the song and fatigue resistance.

5, steel wire braided hose length large, φ32 length of 20 meters or more, φ25 the following can be connected for more than ten meters or even meters.

1, Hose special selection made with synthetic rubber, has excellent oil resistance, heat aging resistance.

2, hose bearing pressure, pulse superior performance.

3, tube linked closely together, use a soft, small deformation under pressure.

4. Hose has an excellent resistance around the song and fatigue resistance.

5, steel wire braided hose length large, φ32 length of 20 meters or more, φ25 the following can be connected for more than ten meters or even meters.

2015年10月21日星期三

Parher wire braided hose used hydraulic support the mine

Parher wire braided hose used hydraulic support the mine, oil field exploitation, suitable for construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various industrial sectors mechanization and automation of hydraulic systems petroleum-based transport in a certain pressure and temperature (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricants) fluids, water-based liquid (such as emulsion, oil-water emulsion, water), gas and liquid transmission with . Working condition, no leakage, not from the head, high safety factor, long life, according to user needs design and production of special-shaped connector fitting.

2015年10月16日星期五

Parher wire braided hydraulic hose is mainly used for aircraft fuel

Parher wire braided hydraulic hose is mainly used for aircraft fuel, hydraulic support the mine, oil exploration, the hydraulic system of construction hydraulic pipe crimping machine, used for transporting high temperature, high pressure kerosene, oil, oil (explosive media), to achieve pressure Service delivery. parher wire braided hydraulic hose is mainly composed of a liquid-resistant synthetic rubber inner layer, middle layer, Ⅰ, Ⅱ, Ⅲ layer steel wire braid, weather-resistant synthetic rubber outer layer, the inner layer has a transmission medium under pressure, Protective effects of wire from erosion, outer layer to protect wire from damage, wire layer is a reinforcing material, from the enhancement.

2015年10月11日星期日

Pipe fittings commonly used in general

hydraulic fittings and hose connector tool pipeline between the connection point between elements can be removable and pipes. Serves as an indispensable role in the tube, it is the two hydraulic pipes constitute one of the main parts. Has a variety of types of pipe fittings, pipe fittings commonly used in general can be divided into two kinds of hardware fittings and hose fittings. If, pursuant to pipe fittings and pipe connections to points, hardware fittings have flared, ferrule and welded three, hose fittings are mainly withhold type hose fittings.

2015年10月6日星期二

hydraulic connector standard

Card sets of pipe joints of the most important aspects of the pre-installed,

directly affects the reliability of sealing. Generally require a dedicated pre-

heater. The small diameter of t he connector in a vise on the pre-installed. In hydraulic adapter fittings practice, a connector as a parent, the nut and ferrule compression tube can. Card sets straight fittings, ferrule end straight-through connected to the head, the type of ferrule tube fittings. I found that even if the same factory shipment, the depth of the tapered hole in the connector body on these types are often not the same hydraulic hose clamps result is caused by a leak, but this is often overlooked. The correct approach is that the tube at one end with what kind of connector body connection, the connection end of the corresponding pre-installed with the same type of connector, so to avoid leakage problems.

directly affects the reliability of sealing. Generally require a dedicated pre-

heater. The small diameter of t he connector in a vise on the pre-installed. In hydraulic adapter fittings practice, a connector as a parent, the nut and ferrule compression tube can. Card sets straight fittings, ferrule end straight-through connected to the head, the type of ferrule tube fittings. I found that even if the same factory shipment, the depth of the tapered hole in the connector body on these types are often not the same hydraulic hose clamps result is caused by a leak, but this is often overlooked. The correct approach is that the tube at one end with what kind of connector body connection, the connection end of the corresponding pre-installed with the same type of connector, so to avoid leakage problems.

2015年10月1日星期四

construction machinery closed hydraulic system installation and commissioning

A large number of construction machinery, especially imported equipment, hydraulic drive and hydraulic drive is very common, such as tunnel boring machines, large tonnage transported beam cars, cranes, lifts truck, paver, excavators, b ulldozers and other . Hydraulic closed loop low energy consumption, compact and easy to achieve continuously variable transmission, has been widely used in the hydraulic system, but compared with the open loop, closed loop installation and debugging difficult to have a high and technical requirements, the following closed loop installation and commissioning of the main points to do a brief summary.

Before You Install hydraulic fittings

1.1 to maintain the cleanliness of the system components: carefully check the pumps and motors as well as all system components: fuel tank, piping, valves, fittings, radiators, etc., to ensure that no damage, pollution-free, valve block processing parts of the chip to clean up and cleaning.

1.2 hydraulic oil clean: Note the degree of contamination and humidity of the oil, to avoid any dirt into the tank. Fuel must go through the filter inside the tank is coated with the c oating must be compatible with the use of oil.

2 implementation of the installation process:hydraulic adaptors

2.1 to prohibit the use of force acting on the hydraulic system to avoid piping systems and components to withstand lateral forces and internal stress, we must pay attention to protect the piping system.

2.2 prohibit the use of twine, adhesive used as sealing materials, otherwise they will contaminate the system, and may result in system failure.

2.3 the right hose layout to avoid torsion of the hose, hold back the strength, abrasion and bump.

2.4 system, the connection must meet the recommended standard, all system piping to be joined and sealed to be reliable, no leakage phenomenon.

3 put into operation, commissioning hydraulic adapter fittings

If the hydraulic system requires the installation has been completed, you can begin to put into operation, the hydraulic system debugging. Before commissioning the hydraulic tank to join as much as possible and clean the hydraulic oil to fuel injection pump, motor shell, the primary system piping, mainly due to the viscosity of the oil, pipelines, pump suction line did not break out the air, plus debugging offline installers within 30 seconds the speed of the diesel engine from the startup surge speed to maximum speed, and fill the pump early wear and tear is inevitable.

Before You Install hydraulic fittings

1.1 to maintain the cleanliness of the system components: carefully check the pumps and motors as well as all system components: fuel tank, piping, valves, fittings, radiators, etc., to ensure that no damage, pollution-free, valve block processing parts of the chip to clean up and cleaning.

1.2 hydraulic oil clean: Note the degree of contamination and humidity of the oil, to avoid any dirt into the tank. Fuel must go through the filter inside the tank is coated with the c oating must be compatible with the use of oil.

2 implementation of the installation process:hydraulic adaptors

2.1 to prohibit the use of force acting on the hydraulic system to avoid piping systems and components to withstand lateral forces and internal stress, we must pay attention to protect the piping system.

2.2 prohibit the use of twine, adhesive used as sealing materials, otherwise they will contaminate the system, and may result in system failure.

2.3 the right hose layout to avoid torsion of the hose, hold back the strength, abrasion and bump.

2.4 system, the connection must meet the recommended standard, all system piping to be joined and sealed to be reliable, no leakage phenomenon.

3 put into operation, commissioning hydraulic adapter fittings

If the hydraulic system requires the installation has been completed, you can begin to put into operation, the hydraulic system debugging. Before commissioning the hydraulic tank to join as much as possible and clean the hydraulic oil to fuel injection pump, motor shell, the primary system piping, mainly due to the viscosity of the oil, pipelines, pump suction line did not break out the air, plus debugging offline installers within 30 seconds the speed of the diesel engine from the startup surge speed to maximum speed, and fill the pump early wear and tear is inevitable.

2015年9月26日星期六

Resistance to foaming of the hydraulic oil is better

1) shall not contain steam, air and other easy to gasification and gas impurities,or from the bubble, so that the work to occur flutter npt pipe fittings move, affecting the smooth working. Mass fraction o f water Germany shall not exceed 0.025%, the formation of water vapor, water will deteriorate the performance of the use of oil and impact of low-temperature work. Resistance to foaming of the hydraulic oil is better, the defoaming stronger. tube fitting Mineral oil usually can be dissolved in the atmosphere of 5% to 10% air, which is the main bubble to reason. Hydraulic pump oil absorption tube seal is not good to improper teflon hose hydraulic fittings installation or management, will produce the foam, it makes the hydraulic pump to generate noise and vibration dynamic characteristics of deterioration and therefore requires the hydraulic oil can be quickly and fully to defoaming, otherwise it will create the power loss increases, the temperature rise, The action is not stable.

2) erosion of parts and damage seals, that does not contain water-soluble acid and alkali ingredients.

3) in the working temperature and pressure, with excellent lubrication, shear stability and film strength.

4) chemical stability. Should not be in the process of storage and work production of oxide colloid, long-term use is not degenerate. When the system temperature degrees, pressure and flow rate changes, still maintain its original character, in the course of deterioration, no precipitation of asphalt, tar and other glial precipitation.

5) to minimize the impurities in the oil, does not allow precipitation to avoid wear and tear parts, clogging pipes and hydraulic components, affecting the system job.

2) erosion of parts and damage seals, that does not contain water-soluble acid and alkali ingredients.

3) in the working temperature and pressure, with excellent lubrication, shear stability and film strength.

4) chemical stability. Should not be in the process of storage and work production of oxide colloid, long-term use is not degenerate. When the system temperature degrees, pressure and flow rate changes, still maintain its original character, in the course of deterioration, no precipitation of asphalt, tar and other glial precipitation.

5) to minimize the impurities in the oil, does not allow precipitation to avoid wear and tear parts, clogging pipes and hydraulic components, affecting the system job.

2015年9月21日星期一

the seal damage affect the machining industry on the maintenance of hydraulic equipment

the seal damage affect the machining industry on the maintenance of hydraulic machines, hydraulic transmission is widely used, such as various types of semi-automatic hydraulic transmission lathe. During use, these machines often appear, such as impact, reptiles and other fault diagnosis and mai ntenance, often in the hydraulic control elements (such as various types of pumps, monoblock hydraulic valves) can not find the cause of the malfunction, resulting in maintenance work in trouble. The final of such failure or often on the implementation of the components to find the reasons, that the cylinder piston sealing elements of serious wear and tear caused by. Class phenomenon especially in the \"O\" ring to see more.

2015年9月16日星期三

hydraulic plate bending machine structural characteristics

Hydraulic plate bending machine structure and characteristics:

(1) hydraulic drive, the machine at both ends of the fuel tank is placed in the slider, the direct drive slide work.

(2) using the machinery of block structure, stable and reliable.

(3) slide stroke motor fast tune, manual fine-tuning, the counter display.

(4) Solid steel welded construction of sufficient strength and rigidity.

(5) slider synchronization mechanism with torsion bar forced synchronization.

(6) Wedge deflection compensation agencies, in order to guarantee access to high bending accuracy.

Hydraulic plate bending machine, hydraulic hose clamps cylinder, end caps, cylinder, the outer piston rod flange set, piston rod, screw, nut and gland; end caps fixed in the cylinder at one end and screw sets , the other end of the fixed nut and gland in the cylinder, the outer piston rod located in the cylinder body, the flange is to be placed on the outer piston rod piston side of the piston within the piston rod end inserted into the outer piston rod within the piston fixed installation of the rod end of the rod end cap, within the piston rod within the opening oil duct. Hydraulic fittings cylinder more than the traditional kind hydraulic cylinder a rod chamber and the rod chamber, and thus has a unique quick drive function in the hydraulic system of the same driving conditions, fuel tanks owned or weightless out knife conditions still can be easily two growth; screw sets of contact with the force area is much larger than the traditional bending machine, hydraulic cylinder adjustment nut, thereby increasing the contact stiffness and stability, to ensure better accuracy of the limit.

(1) hydraulic drive, the machine at both ends of the fuel tank is placed in the slider, the direct drive slide work.

(2) using the machinery of block structure, stable and reliable.

(3) slide stroke motor fast tune, manual fine-tuning, the counter display.

(4) Solid steel welded construction of sufficient strength and rigidity.

(5) slider synchronization mechanism with torsion bar forced synchronization.

(6) Wedge deflection compensation agencies, in order to guarantee access to high bending accuracy.

Hydraulic plate bending machine, hydraulic hose clamps cylinder, end caps, cylinder, the outer piston rod flange set, piston rod, screw, nut and gland; end caps fixed in the cylinder at one end and screw sets , the other end of the fixed nut and gland in the cylinder, the outer piston rod located in the cylinder body, the flange is to be placed on the outer piston rod piston side of the piston within the piston rod end inserted into the outer piston rod within the piston fixed installation of the rod end of the rod end cap, within the piston rod within the opening oil duct. Hydraulic fittings cylinder more than the traditional kind hydraulic cylinder a rod chamber and the rod chamber, and thus has a unique quick drive function in the hydraulic system of the same driving conditions, fuel tanks owned or weightless out knife conditions still can be easily two growth; screw sets of contact with the force area is much larger than the traditional bending machine, hydraulic cylinder adjustment nut, thereby increasing the contact stiffness and stability, to ensure better accuracy of the limit.

2015年9月11日星期五

Forging flange hydroforming principle of hydraulic machines

Forging flange hydroforming principle of hydraulic machines, such as powder molding products, plastic molding, cold (hot) extrusion metal forming, sheet steel, as well as the horizontal pressure welding elbow, turned through the correction process sewage pump hydraulic forming parts are usually only need one set of molds, and stampings are mostly multi-sets of molds. The meter can reduce the amount of subsequent machining and assembly welding. Chiller cooling area increased by 43% to radiator support, for example, the solder joint is reduced from 174 to 20, the process is reduced from 13 to 6 66% increase in productivity. Angle seat valve, reducing the number of parts and molds, improve the rigidity and strength, reduce production costs has obvious technical and economic advantages, especially in the automotive industry has been more and more applications in the industrial field. Compared with the conventional stamping process, hydroforming technology in reducing the weight of the radiator support part to reduce from 17 to 10. Its fundamental principle is based on the pipe to impose ultra-high pressure liquid inside the pipe as a blank, at th e same time, both ends of the tube by axial thrust is applied, feeding.

Reduce production costs. According to the part of statistical analysis has been applied hydraulic forming, hydroforming production costs 15% to 20% lower than average stampings, lower mold costs.9000psi flange together of the two external forces, the tube material plastic deformation and fit, and ultimately with the mold cavity wall, the shape and accuracy to meet the technical requirements of the hollow parts. Hydroforming stamping parts to reduce from 20% to 40%; the hollow stepped shaft parts can be reduced from 40% to 50% of the weight. Improve the strength and stiffness, fatigue strength, such as hydroforming of radiator support, the stiffness in the vertical direction can be increased by 39%, the horizontal direction can be increased by 50%.

Polyurethane stamping and welding process compared to the hydroforming technology and process the following key benefits: hydroforming, also known as hydroforming, hydroforming typical part of the car engine bay, radiator support, engine bay parts reduced from six to one to reduce the quality of material savings. Reduce the number of parts and molds, and reduce tooling costs. Valve test bench hydraulic forming (hydroforming) for the realization of structural lightweight advanced manufacturing technology.

Welding flange forging the technical parameters of the heating machine:hydraulic flange

Model: WH-VIII-10 0 input power: 100KVA Input voltage: three - phase 380V 50-60Hz oscillation frequency :15-25KHZ15-35KHZ volume: the main 650 × 480 × 1440mm3 points 500 × 800 × 580mm3

Forging a pledge of the heating machine: a long-term product quality tracking service. (2) the product of technical guidance, equipment installation and commissioning. (3) technical training for operators. The product to perform three packs of policy within one year of free maintenance, long-term provision of technical services and spare parts. Forging the high reliability of the heating machine: modular, integrated, highly reliable guarantee .5. Installation is simple: only power supply and water pipes, 10 minutes to be completed by .6. Easy to operate: few minutes to learn.

Forging heating machine has a certain technical parameters and performance can have an important effect in the specific use and value, in stric t accordance with appropriate standards and performance, to show the good performance of the operating contribution.

Reduce production costs. According to the part of statistical analysis has been applied hydraulic forming, hydroforming production costs 15% to 20% lower than average stampings, lower mold costs.9000psi flange together of the two external forces, the tube material plastic deformation and fit, and ultimately with the mold cavity wall, the shape and accuracy to meet the technical requirements of the hollow parts. Hydroforming stamping parts to reduce from 20% to 40%; the hollow stepped shaft parts can be reduced from 40% to 50% of the weight. Improve the strength and stiffness, fatigue strength, such as hydroforming of radiator support, the stiffness in the vertical direction can be increased by 39%, the horizontal direction can be increased by 50%.

Polyurethane stamping and welding process compared to the hydroforming technology and process the following key benefits: hydroforming, also known as hydroforming, hydroforming typical part of the car engine bay, radiator support, engine bay parts reduced from six to one to reduce the quality of material savings. Reduce the number of parts and molds, and reduce tooling costs. Valve test bench hydraulic forming (hydroforming) for the realization of structural lightweight advanced manufacturing technology.

Welding flange forging the technical parameters of the heating machine:hydraulic flange

Model: WH-VIII-10 0 input power: 100KVA Input voltage: three - phase 380V 50-60Hz oscillation frequency :15-25KHZ15-35KHZ volume: the main 650 × 480 × 1440mm3 points 500 × 800 × 580mm3

Forging a pledge of the heating machine: a long-term product quality tracking service. (2) the product of technical guidance, equipment installation and commissioning. (3) technical training for operators. The product to perform three packs of policy within one year of free maintenance, long-term provision of technical services and spare parts. Forging the high reliability of the heating machine: modular, integrated, highly reliable guarantee .5. Installation is simple: only power supply and water pipes, 10 minutes to be completed by .6. Easy to operate: few minutes to learn.

Forging heating machine has a certain technical parameters and performance can have an important effect in the specific use and value, in stric t accordance with appropriate standards and performance, to show the good performance of the operating contribution.

2015年9月6日星期日

the hydraulic piping systems technical information - fittings and flanges

In the high quality requirements of hydraulic lines or other piping systems, we recommend the use of non-welded connection technology (fittings and flanges, etc.), because of the high reliability of non-welded connection system and its i nherent high in all piping Cleanliness. This connection technology used depends on the system working pressure and pipe size. Material depends on the specific conditions (or the customer s specific hydraulic flange requirements).

For greater than or equal to 25mm piping, we recommend using the GS-37 ° Flare Flange and GS-Retain Ring System. Less than 25mm piping, we recommend using the connector, tube end forming the connector ferrule connector, or 37 ° JIC expansion port, depending on the specific conditions and design requirements.metric hydraulic hose fittings

2015年9月1日星期二

Hydraulic hose during use should pay attention to the following points

Hydraulic hose during use should pay attention to the following points:

1, Long-term use of the hose clamps should be checked regularly. (The degree of aging and skin abrasion, wear the joint proposal checked once a week).

2, High pressure hose surface cleaning. (Production materials daily cleaning hose surface to keep clean, clear focus on the hose surface corrosive material)

3, When the hose regularly and friction surface contact, use protective liner. Reduce the friction coefficient, increase the service life and prevent aging.

4, Has been used hoses, take a long time when not material to tube cleaned, and then pass into the media kept closed.

5. Do not hose when the hose storage place outdoors. Or because of other factors caused by pollution and sunshine hose aging.

1, Long-term use of the hose clamps should be checked regularly. (The degree of aging and skin abrasion, wear the joint proposal checked once a week).

2, High pressure hose surface cleaning. (Production materials daily cleaning hose surface to keep clean, clear focus on the hose surface corrosive material)

3, When the hose regularly and friction surface contact, use protective liner. Reduce the friction coefficient, increase the service life and prevent aging.

4, Has been used hoses, take a long time when not material to tube cleaned, and then pass into the media kept closed.

5. Do not hose when the hose storage place outdoors. Or because of other factors caused by pollution and sunshine hose aging.

2015年8月25日星期二

Quick connector fitting standards for special heavy-duty design

Hydraulic fittings quick connector fitting standards for special heavy-duty design, the box made of chrome-plated steel, male connectors and female connectors are locking sleeve hardened, resistant hydraulic quick coupling Jingjiang City, the art spring plant

Pressure and good fatigue resistance: a two-stage seal, no leakage: with safety lock function.

This connector does not require the use of a tool, but also to achieve rapid assembly and disassembly of metric pipe fittings, he had open at both ends closed and open ends of the two structures.

Pressure and good fatigue resistance: a two-stage seal, no leakage: with safety lock function.

This connector does not require the use of a tool, but also to achieve rapid assembly and disassembly of metric pipe fittings, he had open at both ends closed and open ends of the two structures.

2015年8月18日星期二

Hydraulic adaptors requirements

Hydraulic adaptors requirements:

1, to avoid heavy backlog of vehicles and other high-pressure hose, causing the flow rate and pressure of the fluid inside the hose is restricted. Do not hose drag on rough surfaces or sharp objects.

2, hose twisted or tangled together, do not pull the hose fittings.

3, when the hose often and friction surface contact, use protection hose, protective bushings increase service life.

4, away from heat.

5. The surface of the hose away from corrosive materials.

6, the above will result in poor use of violence pipe and mechanical damage, shorten the service life of high-pressure hose.

1, to avoid heavy backlog of vehicles and other high-pressure hose, causing the flow rate and pressure of the fluid inside the hose is restricted. Do not hose drag on rough surfaces or sharp objects.

2, hose twisted or tangled together, do not pull the hose fittings.

3, when the hose often and friction surface contact, use protection hose, protective bushings increase service life.

4, away from heat.

5. The surface of the hose away from corrosive materials.

6, the above will result in poor use of violence pipe and mechanical damage, shorten the service life of high-pressure hose.

2015年8月11日星期二

Hydraulic Hose features

Hydraulic hose manufacturers as we introduce the characteristics of hydraulic hose.

1. Hose special selection made with synthetic rubber, has excellent oil resistance, heat aging resistance.

2, hose bearing pressure, pulse superior performance.

3, tube linked closely together, use a soft, small deformation under pressure.

4. Hose has an excellent resistance around the song and fatigue resistance.

5, steel wire braided hose length large, Φ32 length of 20 meters or more, Φ25 the following can be even more than ten meters or even meters.

1. Hose special selection made with synthetic rubber, has excellent oil resistance, heat aging resistance.

2, hose bearing pressure, pulse superior performance.

3, tube linked closely together, use a soft, small deformation under pressure.

4. Hose has an excellent resistance around the song and fatigue resistance.

5, steel wire braided hose length large, Φ32 length of 20 meters or more, Φ25 the following can be even more than ten meters or even meters.

2015年8月4日星期二

Hydraulic hose uses

Hydraulic hose uses:

Wire braided hydraulic hose is mainly used for mine hydraulic support, oil exploitation, suitable for construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various industrial sectors mechanization and automation of hydraulic petroleum-based system has a certain pressure and temperature (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricants) fluids, water-based liquid (such as emulsion, oil-water emulsion, water), gas and liquid transmission use.

Wire braided hydraulic hose is mainly used for mine hydraulic support, oil exploitation, suitable for construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various industrial sectors mechanization and automation of hydraulic petroleum-based system has a certain pressure and temperature (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricants) fluids, water-based liquid (such as emulsion, oil-water emulsion, water), gas and liquid transmission use.

2015年7月28日星期二

What used american fittings

What used american fittings?

About hydraulic fittings: a system consists of many parts and components composition, since each "fit" of these parts, hydraulic machines in order to form, each component of the system are "parts" of the. There are a number of parts of a shorter life, or easily damaged, we must be prepared in advance of these consumables, for the repair of use, so as not to wait for the bad parts affecting production, these pre-prepared spare parts called "Spare" ʱ?? Accessories and spare parts can be the same thing, but also not. General outsourcing, bought to use more call accessories, or purchased or homemade, ready for a long time to use the most is called spare parts. Know this, we should know what we used hydraulic fittings.

About hydraulic fittings: a system consists of many parts and components composition, since each "fit" of these parts, hydraulic machines in order to form, each component of the system are "parts" of the. There are a number of parts of a shorter life, or easily damaged, we must be prepared in advance of these consumables, for the repair of use, so as not to wait for the bad parts affecting production, these pre-prepared spare parts called "Spare" ʱ?? Accessories and spare parts can be the same thing, but also not. General outsourcing, bought to use more call accessories, or purchased or homemade, ready for a long time to use the most is called spare parts. Know this, we should know what we used hydraulic fittings.

2015年7月21日星期二

Swivel fittings

Swivel fittings working speed: 3000rpm, working temperature: 343 °, 25 MPa working pressure.

female swivel fitting to support a number of passages -42-pass.

Simultaneous transmission of gas, liquid, oil, a variety of media.

The compact design of the structure, flange connection, effectively integrated into the customer equipment among.

The use of America's most advanced surface treatment technology.

female swivel fitting to support a number of passages -42-pass.

Simultaneous transmission of gas, liquid, oil, a variety of media.

The compact design of the structure, flange connection, effectively integrated into the customer equipment among.

The use of America's most advanced surface treatment technology.

2015年7月14日星期二

Introduction Parher company

Parher is a company specialized in the production and sale of all kinds of refrigeration and air conditioning, hydraulic fitting, pneumatic and fluid control products and components of the company. The company offers high-quality products, it is widely used in all walks of life: refrigeration and air conditioning, light industry, heavy machinery,petrochemicals, power plants, automotive and aerospace markets. Manufacturer of the world's largest professional hydraulic fittings, hose assemblies, tube fittings, quick connectors products, hydraulic adaptors, hydraulic valves and other products group.

2015年7月7日星期二

Structure and characteristics of the stainless steel metal hose

Structure and characteristics of the stainless steel metal hose: It is made of stainless steel bellows one or more layers of wire braided hose or steel nets, both ends with connector or flange head for flexible delivery of various media elements. Corrosion, high temperature, low temperature (-196 ℃ ~ + 420 ℃), light weight, small size, flexibility is good. Widely used in aviation, aerospace, petroleum, chemical, metallurgical, power, paper, wood, textile,construction,pharmaceutical, food, tobacco, transportation and other industries.

2015年6月30日星期二

Applications of wire braided hydraulic hose

Applications of wire braided hydraulic hose is used for mine hydraulic support, oil exploitation, suitable for construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various industrial sectors mechanization and automation of hydraulic hose crimping machine system has a certain pressure and temperature (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricants) fluids, water-based liquid (such as emulsion, oil-water emulsion, water), gas and liquid transmission use. Its working temperature: Oil -40 ℃ - + 100 ℃, air -30 ℃ - + 50 ℃, less water emulsion + 80 ℃.

2015年6月23日星期二

High-pressure hydraulic hose

Hydraulic hose machine is for mine hydraulic support, oil field development, construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various industrial sectors mechanization and automation of the hydraulic machines has a certain pressure and temperature petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricants) and water-based liquid (such as emulsion, oil-water emulsion, water) and liquid transmission pipeline. Due to the different kinds of mechanical equipment connected to all forms of joints are different.

2015年6月16日星期二

How to identify wire braided hydraulic hose Model

How to identify wire braided hydraulic hose Model

As GB Example: Ruhr / GB / T3683-2011 / 2SN / 16 / 25MPa / 2Q12

1.Ruhr is manufacturing name or logo

2.GB/T3683-2011 is the implementation of standards

3.16 is the nominal diameter

4.2SN is typed

5.Maximum operating pressure is 25MPa

As GB Example: Ruhr / GB / T3683-2011 / 2SN / 16 / 25MPa / 2Q12

1.Ruhr is manufacturing name or logo

2.GB/T3683-2011 is the implementation of standards

3.16 is the nominal diameter

4.2SN is typed

5.Maximum operating pressure is 25MPa

2015年6月9日星期二

Parher steel braided hydraulic hose product structure and performance

Parher wire braided hydraulic hose product structure and performance:

The tube: Oil resistant synthetic rubber.

Reinforcement: one high tensile steel wire braid (1W / B)

Cover: black oil, corrosion resistant synthetic rubber, look for a mat surface.

Temperature range: -40 ℃ to +100 ℃

Such withhold hose fittings without stripping outer plastic. For construction machinery and hydraulic equipment continuous operation with good heat oil anti-pulse performance.

The tube: Oil resistant synthetic rubber.

Reinforcement: one high tensile steel wire braid (1W / B)

Cover: black oil, corrosion resistant synthetic rubber, look for a mat surface.

Temperature range: -40 ℃ to +100 ℃

Such withhold hose fittings without stripping outer plastic. For construction machinery and hydraulic equipment continuous operation with good heat oil anti-pulse performance.

2015年5月26日星期二

Wire reinforced hydraulic rubber hose main application

Wire reinforced hydraulic rubber hose is mainly used for mine hydraulic support, oil exploitation, suitable for construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various industrial sectors mechanization and automation of hydraulic banjo fittings petroleum-based system has a certain pressure and temperature (such as mineral oil, soluble oil, monoblock hydraulic valves, fuel oil, lubricants) fluids, water-based liquid (such as emulsion, oil-water emulsion, water), gas and liquid transmission use.

2015年5月20日星期三

Hydraulic hose use

Mainly used for mine hydraulic support, oil field development, suitable for construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, machine tools and various industrial sectors mechanization and automation of the hydraulic pipe crimping machine system has a certain pressure and the temperature of the petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricants) and water-based liquid (such as emulsion, oil-water emulsion, water) and liquid transmission. reusable hydraulic hose fittings rubber and plastic materials, also known as rubber hose, is a new type of hose, its resistance to corrosion and energy-saving effect.

2015年5月14日星期四

Of hydraulic, pneumatic and sealing industry development process

Our american hydraulic adapter(including hydraulic, the same below), pneumatic and seal industrial development process can be divided into three stages: the early 1950s to early 1960s infancy; 60 to 70 years of specialized production System growth stage; 80 to 90 years of rapid development stage. Among them, the hydraulic industry in the early 1950s imitated Soviet grinders, broaching, start copying lathes and other flat seal metric hydraulic fittings transmission, hydraulic components plant by the machine hydraulic workshop production, production for own use from the machine tool industry production. Into the 1960s, the application of hydraulic technology from the machine gradually extended to agricultural machinery and construction machinery and other fields, originally attached to the OEM hydraulic workshop some independence, and become a professional manufacturer of hydraulic parts. By the late 60s, early 70s, with the development of production mechanization, particularly in the second car factory to provide efficient, driven automation equipment, british hydraulic adapter components manufacturing has experienced rapid development of the situation, a group of SMEs It has become a professional manufacturer of hydraulic parts. 1968 Chinese hydraulic components production has nearly 200,000; 1973 in machine tools, agricultural machinery, engineering machinery and other industries, professional production of hydraulic parts factory has grown to more than 100, the annual output more than 1 million, a separate hydraulic parts Manufacturing has taken shape. In this case, hydraulic product development from the imitation of the Soviet Union for the introduction of technology and products to design a combination of product, pressure, and high pressure development, and the development of electro-hydraulic servo valves and systems, further expanding hydraulic applications. Hydraulic pneumatic industry started later than a few years, until 1967 to start building a professional factory pneumatic components, pneumatic components just as commodity production and sales. Containing rubber seals, mechanical seals and seal flexible graphite sealing industry, in the early 1950s from the production of ordinary O-rings, seals and other extruded rubber seals and asbestos sealing products start to the early 1960s, began to develop and produce mechanical seals and flexible graphite sealing products. 70s in the burning of the original part, a machine unit, the Ministry of Agricultural Machinery Systems, a group specializing in the production plants have been established and officially formed industry, laid the foundation for the development of the growth of the seal industry.

2015年5月7日星期四

DKJ card sets of metal hose connectors, can no threaded pipe and hose connections, save the threading process, just to drive the screw into the can. Metal joints made of zinc alloy die-casting, zinc plated, brushed or chrome; compact, high strength. Steel and metal hose connection is reliable, beautiful appearance. The metric pipe fittings of card sets for the metal hose is connected to the top of the steel pipe with no threads. Adapter metal hose: JS type, JSH type, JSB type, JSHG type. Adaptation steel: thin steel wire tube, black, galvanized iron pipe (water, gas pipes).

2015年4月11日星期六

hydraulic fittings manufacturers

hydraulic fittings manufacturers

2015年4月6日星期一

wire braided hydraulic hose

wire braided hydraulic hose

2015年2月28日星期六

Deduction of operating Tutorials

Deduction of operating Tutorials

1 sample with a ruler to measure the length of the hose

2 metal joints using a caliper measurement data , the sample was observed inside diameter hose

3 Prepare hoses and fittings needed

4 with a cutting hydraulic hose ends to cut the required length of the hose , the hose bore cleaning

5 skiving machine with outer rubber hose stripped , and then insert a metal hose connector sleeve.

Note: You must peel off the outer layer of rubber hose

6 straight pin plug connector metal hose directly to the bottom

7 . Measuring hose and hose samples are the same length

8 shrink tube with no taper reusable hose fittings

9 The transfer hose will be withheld by the provisions of the Data Locator quasi

10. Began to withhold hose, you can use the manual button or using the foot withhold withhold button

11 hose crimping in place , you can locate the alarm sounds , and then press the button to open the mold

12. Withhold withhold data caliper measurement is completed , using probes to detect

13 hose to the required data can be withheld

14 Withhold completed

1 sample with a ruler to measure the length of the hose

2 metal joints using a caliper measurement data , the sample was observed inside diameter hose

3 Prepare hoses and fittings needed

4 with a cutting hydraulic hose ends to cut the required length of the hose , the hose bore cleaning

5 skiving machine with outer rubber hose stripped , and then insert a metal hose connector sleeve.

Note: You must peel off the outer layer of rubber hose

6 straight pin plug connector metal hose directly to the bottom

7 . Measuring hose and hose samples are the same length

8 shrink tube with no taper reusable hose fittings

9 The transfer hose will be withheld by the provisions of the Data Locator quasi

10. Began to withhold hose, you can use the manual button or using the foot withhold withhold button

11 hose crimping in place , you can locate the alarm sounds , and then press the button to open the mold

12. Withhold withhold data caliper measurement is completed , using probes to detect

13 hose to the required data can be withheld

14 Withhold completed

2015年2月24日星期二

Carrying the locator pull down, to avoid accidentally crashed

Carrying the locator pull down, to avoid accidentally crashed .

2 , in order to prolong the life of your jic hydraulic fittings , no accidents , we must add the original hydraulic oil.

3 , before each use , pay attention to the oil with a small brush to brush the nose cone front lubricants ( oil or hydraulic oil ) .

4, do not withhold rusted joints and pipes , to prevent impurities fall inside the nose .

Conservation Matters

1 , often moving surface injection mold base to wear lubricants.

2 , non- pressure pipe machine hours, please cover dust cover to prevent debris falling into the mold base .

3 , hydraulic oil tank over time specified by the manufacturer of hydraulic oil should be replaced , or the visual oil level gauge , if the hydraulic oil has been oxidized black bias must be replaced.

Hose crimping machine maintenance on the importance of this simple three-step , the most important thing is the staff to do a better pressure pipe reusablehydraulic fittings maintenance.

2 , in order to prolong the life of your jic hydraulic fittings , no accidents , we must add the original hydraulic oil.

3 , before each use , pay attention to the oil with a small brush to brush the nose cone front lubricants ( oil or hydraulic oil ) .

4, do not withhold rusted joints and pipes , to prevent impurities fall inside the nose .

Conservation Matters

1 , often moving surface injection mold base to wear lubricants.

2 , non- pressure pipe machine hours, please cover dust cover to prevent debris falling into the mold base .

3 , hydraulic oil tank over time specified by the manufacturer of hydraulic oil should be replaced , or the visual oil level gauge , if the hydraulic oil has been oxidized black bias must be replaced.

Hose crimping machine maintenance on the importance of this simple three-step , the most important thing is the staff to do a better pressure pipe reusablehydraulic fittings maintenance.

2015年2月20日星期五

On the use of hose crimping machine specification and maintenance measures

On the use of hose crimping wire braidedhydraulic hose specification and maintenance measures

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction .

Operating

1 , plus a full 46 # hydraulic oil 50kg ( preferably a genuine original oil ) .

2 , locators installation: first locator inserted in front of the nose ( Note : Locator can be directly inserted into the nose ) , the other end plugs in the electrical control box inside the corresponding socket.

3 , connect the power , if you are using a three-phase motor , be careful not to pick inversion (top : a motor fan clockwise direction is forward ) .

4, after the completion of the above steps , you can turn the pressure test .

5 , the use of locator : spin down more than a week each pressed into 1mm, every positive spin a grid of 0.01mm, and so on, the same size hose , fittings, metal fittings first reached the required pressure , no longer need to move Locator , has been finished to the specifications of the pressure , the result is fully consistent with data compression , when you complete the first root tubing pressure test , you have learned , and the remaining is gradually skilled.

Precautions

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction .

Operating

1 , plus a full 46 # hydraulic oil 50kg ( preferably a genuine original oil ) .

2 , locators installation: first locator inserted in front of the nose ( Note : Locator can be directly inserted into the nose ) , the other end plugs in the electrical control box inside the corresponding socket.

3 , connect the power , if you are using a three-phase motor , be careful not to pick inversion (top : a motor fan clockwise direction is forward ) .

4, after the completion of the above steps , you can turn the pressure test .

5 , the use of locator : spin down more than a week each pressed into 1mm, every positive spin a grid of 0.01mm, and so on, the same size hose , fittings, metal fittings first reached the required pressure , no longer need to move Locator , has been finished to the specifications of the pressure , the result is fully consistent with data compression , when you complete the first root tubing pressure test , you have learned , and the remaining is gradually skilled.

Precautions

2015年2月16日星期一

Hose crimping machine for permanent mechanical precision and life on the locking mechanism assembly

Hose crimping machine for permanent mechanical precision and life on the locking mechanism assembly, only selected high-quality steel materials, and the use of a unique heat treatment process. So hose crimping machine long life: the selection, heat treatment, hydraulic hosemachine process rationality and structure are inextricably linked.

Deduction of the machine tips, popularly known as crimping machine, crimping machine is a hydraulic hose fittings for withholding pipe assembly of hydraulic equipment, which will be the supporting metal fittings by deduction of the machine mold shrinkage force exerted by the hydraulic system the metal fittings on the firm withheld supporting hydraulic tubing and rubber hose.

1, dual hydraulic circuit principle of operation, that mouth and contraction movement of the piston back and forth and molds are relying on the power hydraulic power source. Not only does it move smoothly, return quickly, like a spring return, not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy withhold various shaped elbow.

2, the hydraulic system consists of motor, pump, valve, pressure regulator and hydraulic valve with dual hydraulic circuit retreat became a sport, but also in a dual hydraulic circuit from a rapid increase in the oil drain valve, in order to achieve a more rapid return purposes, and the speed is adjustable, noise and system pressure is reduced.

3, in the electrical control system, the control circuit applies PLC circuit, it is easy to repair the circuit, easy maintenance and replacement easy.

4, withhold mold and mold base accumulated error-free hose crimpingmachine process to ensure product after withhold withhold evenly spaced lines, no size head phenomenon.

5, in order to permanently withhold machine mechanical precision and life on the locking mechanism assembly, only selected high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life: the selection, heat treatment, machining process rationality and structure are inseparable!

Deduction of the machine tips, popularly known as crimping machine, crimping machine is a hydraulic hose fittings for withholding pipe assembly of hydraulic equipment, which will be the supporting metal fittings by deduction of the machine mold shrinkage force exerted by the hydraulic system the metal fittings on the firm withheld supporting hydraulic tubing and rubber hose.

1, dual hydraulic circuit principle of operation, that mouth and contraction movement of the piston back and forth and molds are relying on the power hydraulic power source. Not only does it move smoothly, return quickly, like a spring return, not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy withhold various shaped elbow.

2, the hydraulic system consists of motor, pump, valve, pressure regulator and hydraulic valve with dual hydraulic circuit retreat became a sport, but also in a dual hydraulic circuit from a rapid increase in the oil drain valve, in order to achieve a more rapid return purposes, and the speed is adjustable, noise and system pressure is reduced.

3, in the electrical control system, the control circuit applies PLC circuit, it is easy to repair the circuit, easy maintenance and replacement easy.

4, withhold mold and mold base accumulated error-free hose crimpingmachine process to ensure product after withhold withhold evenly spaced lines, no size head phenomenon.

5, in order to permanently withhold machine mechanical precision and life on the locking mechanism assembly, only selected high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life: the selection, heat treatment, machining process rationality and structure are inseparable!

2015年2月12日星期四

widely used , its advantages and technical performance as follows

widely used , its advantages and technical performance as follows :

1 , the operating principle of dual hydraulic circuit , i.e., mouth and contraction of the piston forward and backward movement of the mold and the motive power of the hydraulic power source is generated . Not only does it move smoothly , return quickly , like a spring return , not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy to withhold various shaped elbow.

2 , the hydraulic system by the motor , pump , solenoid valve , relief valve and the hydraulic valve would move back and forth with a double hydraulic circuit , but also in a double hydraulic circuit of a rapid increase in drain oil from the valve passage , in order to achieve more Quick return purposes, and the speed is adjustable , noise and system pressure is reduced.

3 , the electrical control system, the control circuit applies PLC circuit , it is easy to repair circuits , easy maintenance and replacement simple.

4 , mold and die holder withhold cumulative error -free bsp thread fittings process to ensure that the withholding of withholding product evenly spaced lines , no size head phenomenon .

5 , in order to withhold machine permanent mechanical precision and life on the locking mechanism assembly , not only chose the high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life : the selection, heat treatment, 60 Cone seal hose fitting process and the reasonableness of the structure are inseparable

1 , the operating principle of dual hydraulic circuit , i.e., mouth and contraction of the piston forward and backward movement of the mold and the motive power of the hydraulic power source is generated . Not only does it move smoothly , return quickly , like a spring return , not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy to withhold various shaped elbow.

2 , the hydraulic system by the motor , pump , solenoid valve , relief valve and the hydraulic valve would move back and forth with a double hydraulic circuit , but also in a double hydraulic circuit of a rapid increase in drain oil from the valve passage , in order to achieve more Quick return purposes, and the speed is adjustable , noise and system pressure is reduced.

3 , the electrical control system, the control circuit applies PLC circuit , it is easy to repair circuits , easy maintenance and replacement simple.

4 , mold and die holder withhold cumulative error -free bsp thread fittings process to ensure that the withholding of withholding product evenly spaced lines , no size head phenomenon .

5 , in order to withhold machine permanent mechanical precision and life on the locking mechanism assembly , not only chose the high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life : the selection, heat treatment, 60 Cone seal hose fitting process and the reasonableness of the structure are inseparable

2015年2月8日星期日

Over the years, the company is committed fittings and hose connector crimping machine

Over the years, the company is committed fittings and hose connector crimping machine ( reduction of the machine ) and research and development hose accessory products , is now supporting the establishment of partnerships in a number of hydraulic double connectory manufacturer. Companies believe our sincerity and faith put up a bridge , you and I work together to promote the enterprise efficient and harmonious development.

the technical performance hose crimping machine which

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction . Classification crimping machine , such as by using the function can be divided into hydraulic pressure pipe crimping machine , crimping machine brake pipe , air pipe crimping machine , crimping machine , etc. power tubes , such as by mechanical structure can be divided into straight -type crimping machine , double column withhold machine, crimping machine open type , C type crimping machine , such as by control can be divided into electromechanical crimping machine , PLC -style crimping machine , crimping machine CNC type , electro-mechanical crimping double hose connector which is widely used , its advantages and technical performance as follows

the technical performance hose crimping machine which

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction . Classification crimping machine , such as by using the function can be divided into hydraulic pressure pipe crimping machine , crimping machine brake pipe , air pipe crimping machine , crimping machine , etc. power tubes , such as by mechanical structure can be divided into straight -type crimping machine , double column withhold machine, crimping machine open type , C type crimping machine , such as by control can be divided into electromechanical crimping machine , PLC -style crimping machine , crimping machine CNC type , electro-mechanical crimping double hose connector which is widely used , its advantages and technical performance as follows

2015年2月4日星期三

Cartridge - also known as the felling assembly

Cartridge - also known as the felling assembly, which consists of spool and sleeve, springs and seals four kinds of parts. Main function is used to control the direction of the main oil line, pressure and flow.

2 Control cover - from the cover of the embedded micro-pilot control element (throttling plug) as well as other parts and other accessories. It is mainly used to secure and guarantee Cartridge seal; communication control oil and felling the link between the control chamber and implement control.

3 pilot control 74 cone seal fitting on the control cover (also can be installed directly on the manifold body), is the implementation of action for felling Cartridge smaller gauge control valve. Mainly pain ¢ 10 ¢ 6 and the standard diameter solenoid valve, proportional valve, adjustable dampers, buffers, etc.. Felling larger size may need to use a smaller two-way cartridge valves for secondary control. Dimensions comply with ISO and national standards solenoid valve can be interchanged with the installation of similar products at home and abroad.

4 manifold blocks - used to install Cartridge, covers and other control valve control, communication and control circuit of the main oil blocks

2 Control cover - from the cover of the embedded micro-pilot control element (throttling plug) as well as other parts and other accessories. It is mainly used to secure and guarantee Cartridge seal; communication control oil and felling the link between the control chamber and implement control.

3 pilot control 74 cone seal fitting on the control cover (also can be installed directly on the manifold body), is the implementation of action for felling Cartridge smaller gauge control valve. Mainly pain ¢ 10 ¢ 6 and the standard diameter solenoid valve, proportional valve, adjustable dampers, buffers, etc.. Felling larger size may need to use a smaller two-way cartridge valves for secondary control. Dimensions comply with ISO and national standards solenoid valve can be interchanged with the installation of similar products at home and abroad.

4 manifold blocks - used to install Cartridge, covers and other control valve control, communication and control circuit of the main oil blocks

2015年1月31日星期六

High pressure hose assembly

High pressure hose assembly

High pressure hose assembly uses the high quality steel wire braided hose or wire winding hose and hydraulic couplers, the special equipment withhold from. According to user needs to select high-quality carbon steel fittings, stainless steel fittings, brass fittings, aluminum joints, joint form and closely follows the national standard metric threads (JB1891-1900-77), American Standard, British standards, accurate data, reasonable structure , easy to assemble, withholding tight, high temperature, high pressure and pulse operation, no leakage, not from the head, high safety factor, long life, according to user needs and the design and production of special-shaped connector connector.

Second, the use of media and temperature, oil -30 degrees to 80 degrees, the air is -30 degrees to 50 degrees, 0 degrees to 80 degrees water, hydraulic power transmission or delivery of water, gas, oil and pressure medium in order to ensure circulation of the liquid and transfer of liquid energy.

High pressure hose assembly uses the high quality steel wire braided hose or wire winding hose and hydraulic couplers, the special equipment withhold from. According to user needs to select high-quality carbon steel fittings, stainless steel fittings, brass fittings, aluminum joints, joint form and closely follows the national standard metric threads (JB1891-1900-77), American Standard, British standards, accurate data, reasonable structure , easy to assemble, withholding tight, high temperature, high pressure and pulse operation, no leakage, not from the head, high safety factor, long life, according to user needs and the design and production of special-shaped connector connector.

Second, the use of media and temperature, oil -30 degrees to 80 degrees, the air is -30 degrees to 50 degrees, 0 degrees to 80 degrees water, hydraulic power transmission or delivery of water, gas, oil and pressure medium in order to ensure circulation of the liquid and transfer of liquid energy.

2015年1月28日星期三

According to withhold data supporting metal hoses and hose fittings positioning withhold

According to withhold data supporting metal hoses and hose fittings positioning withhold .

Maintenance deduction of the machine

1 keep the nose cone before shrinking machine lubrication , at least twice a day

2 . Regular cleaning nose cone of the machine before shrinking to avoid stolen goods into the nose to keep oil clean

3 Check the motor circuit whether the anomalies , if any, should be excluded

4 Check the oil tank through the window , the oil in place

5 Check the motor , the surface should be clean and free of dust , oil . Complete ministries screw fastening , hood , fan no defect, chassis no cracks .

Talking hose crimping machine works

Works pump hose crimping machine is installed in the hydraulic oil in the tank immersed in silent cooling design to achieve scientific purposes , the motor -driven pumps , hydraulic oil output , push the plunger movement withhold tanks , resulting in mold base radial contraction , and mold on the hose fitting jacket extrusion .

Maintenance deduction of the machine

1 keep the nose cone before shrinking machine lubrication , at least twice a day

2 . Regular cleaning nose cone of the machine before shrinking to avoid stolen goods into the nose to keep oil clean

3 Check the motor circuit whether the anomalies , if any, should be excluded

4 Check the oil tank through the window , the oil in place

5 Check the motor , the surface should be clean and free of dust , oil . Complete ministries screw fastening , hood , fan no defect, chassis no cracks .

Talking hose crimping machine works

Works pump hose crimping machine is installed in the hydraulic oil in the tank immersed in silent cooling design to achieve scientific purposes , the motor -driven pumps , hydraulic oil output , push the plunger movement withhold tanks , resulting in mold base radial contraction , and mold on the hose fitting jacket extrusion .

2015年1月27日星期二

High pressure hose winding wire

High pressure hose winding wire

Product structure type:

Resistant inner layer consists of a liquid, the layer, layer 2 or 4 or 6 wire reinforced layer, the outer layer composition, within the transport layer with a medium under pressure, protect against erosion of the role of the wire, the outer layer protect wire from damage, wire (φ0.3--2.0 reinforced steel) frame material layer is played enhancement.

Product use:

High pressure steel wire reinforced dn series fitting hose is mainly used for mine hydraulic support, oil exploitation, suitable for construction, material handling, forging metallurgy, mining equipment, ships, injection molding machinery, agricultural machinery, tools and various industrial sectors mechanization and automation of the hydraulic system in conveying a certain pressure (the higher pressure) and the temperature of the petroleum-based (such as mineral oil, soluble oil, hydraulic oil, fuel oil, lubricating oil) and the water-based liquid (e.g., emulsions, oil-water emulsion, water) and a liquid drive with a maximum working pressure resistant up 70-100MPa.

Note: This business wire winding hose standard reference GB / T10544-03 standard, DIN20023, SAE100R9 ~ 13 standard, this standard is not suitable for castor oil-based and lipid-based liquid.

Features:

1. Hose special selection made with synthetic rubber, has excellent oil resistance, heat aging resistance.

2. Hose bearing pressure, pulse superior performance.