Web Design And Seo For www.china-webdesign.comThank you for inquiry my hydraulic cutting machine, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/key-hydraulic-hose-cutting-machine-47/

Hydraulic system during the installation of pollution control is also very important, following details:

1 for the manufacture of pollution control

Parts o f the process generally requires a "wet processing" method, that is, all processing operations should be dropping a lubricating fluid or cleaning fluid, to ensure the quality of surface processing.

Two components, parts cleaning

hydraulic hose crimping machineNew hydraulic parts prior to assembly, the old hydraulic contaminated must be washed before use, the cleaning process should do the following:

1) hydraulic assembly and disassembly, cleaning should be consistent with national standards for clean room. Conditions, if any, operating room, preferably pressurized, so that the indoor pressure is higher than outdoors, to prevent indoor air pollution by dust; subject to conditions, but also the operating room should be incommunicado, generally does not allow the hydraulic parts assembly and machining occasionally fitter in the same room, should be the abso lute prohibition of decomposition and assembly of hydraulic components in the open shed, debris or warehouse.

hydraulic blockDisassembly of hydraulic parts, the operator should wear the uniform fiber is not easy to fall off, work caps, to prevent the fibers, dust, hair, dander and other scattered into the hydraulic system caused by human pollution. Smoking, eating in the operating room is strictly prohibited.

2) hydraulic cleaning should be dedicated cleaning stage. Subject to conditions, but also to ensure the cleanliness of the temporary table.

3) The cleaning fluid is allowed to use the same grades of kerosene and hydraulic system oil hydraulic oil.

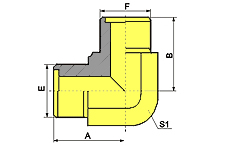

hydraulic manifold4) After cleaning the parts are not allowed to wipe with cotton, hemp, silk and chemical fiber fabrics, to prevent the shedding of fiber contaminat ion parts. With dust particles are not allowed to Part blast (within the Paper Tiger Paper Tiger), when necessary, use compressed air parts.

5) After cleaning the parts are not allowed on the land, concrete, flooring, fitters and assembly work on stage, but should be placed in a container with a lid and into the hydraulic oil.

6) have been cleaned but it would not assembled parts should be placed in the anti-rust oil preservation, damp areas and season to pay attention to anti-rust.

3 hydraulic parts in the assembly of pollution control

1) the hydraulic component assembly should be used "dry assembly" method, that is, after cleaning the parts, in order not to make the cleaning fluid left in the part surface and affect the assembly quality of the part surface is dry before assembly.

2) assembly of hydraulic components For the fight against the prohibition of the use of iron hammer beat, you can use a wooden hamm er, rubber hammer, copper hammer and brass rod.

3) assembly allowed to take the gloves are not allowed to use the fiber fabric, clean the mounting surface to prevent fiber dirt invasive valve.

4) the components of the hydraulic assembly finished components shall be carried out to install, should they all ports blocked with plastic stopper.

4 hydraulic transport of pollution control

Hydraulic components, the components of transport should pay attention to dust, rain, long-distance transport, especially the maritime transport of hydraulic components must use water-resistant paper or plastic wrapping paper, and put the right amount of desiccant, and does not allow rain water, seawater exposure hydraulic parts. Before packing and unpacking should carefully check all ports blocked with a stopper to take timely remedial measures in ports by the light pollution and serious pollution of hydraulic components must be again decomposed cleanin g.

5 hydraulic system assembly of pollution control

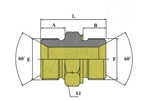

1) The hose must be in the pickling rinse before receiving the actuator before installation to use compressed air blowing. Midway demolition hose to bandage a good hose connector.

2) pipe connector install clean kerosene cleaning and drying with compressed air. Need the raw material with sealed fittings, wrapped around the raw material with time to pay attention to two points: First, the the cis thread direction of winding; Second, the raw material with not more than the threaded end, otherwise, the excess in the tightening process will be thread cut into the system.

3) The hydraulic piping installation of pollution control

Hydraulic pipeline is an important part of the hydraulic system, but also the workload of large-site construction projects, and pipeline installation is vulnerable to pollution. Therefore, the hydraulic pipe pollution control is an important element of the hydraulic system cleaning.

Pipeline installation to clean up the internal particles of impurities, the absolute prohibition of the stones, rags and other debris left in the tube. Pipeline installation process if a long time interrupted, must seal the tube mouth to prevent debris intrusion. In order to prevent welding slag, oxide scale into the system it is recommended that the pipeline welding

The gas shielded arc welding, such as argon arc.

Pipe installed to go through pickling, flushing system, the absolute prohibition of hydraulic components will be connected into the pipeline before processing circuit and even incorporated into the hydraulic system to prevent pollutants invasive tube actuator, control parts.

Pipe pickling is divided into two kinds of slot pickling and circulation pickling, pickling techniques and recipes and there are many. System Flush pickling work after the end of the hydraulic system put into use bef ore the last cleaning measures must ensure that all pipes and hydraulic components rinse to achieve the required cleanliness. System flushing should be divided into two steps. The first site to install the pipe connected into the loop rinse to achieve the requirements of cleanliness and then the control components of the control valve, shunt access loop to the cleanliness rear qualified for flushing.

6 hydraulic fuel tank

Hydraulic tank oiling must check the cleanliness of its internal failure when cleaning; oil by adding to verify its cleanliness; oiling must be filtered, do not allow the oil is injected directly into the hydraulic tank.

7 System Recovery

The system pickling, after washing all the components, piping required with a working circuit. This process should pay particular attention to the cleaning of fittings After connecting, try to avoid demolition, necessary to pay attention to when tied with a clean cloth to ensure that the pipe joints, pipe mouth is not contaminated.

The hydraulic system of pollution control throughout the entire processing and assembly process, every step to take cleaning measures to minimize the hydraulic system contamination, ensure that the hydraulic system can be safely and reliable operation requires the operator.