Web Design And Seo For www.china-webdesign.com

hydraulic fittings suppliers - China Manufacturer

Thank you for inquiry my hydraulic fittings suppliers, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/

ZL04 wheel loaders often a boom in the no-load throttle slowly lifting heavy load does not the fault phenomena.

From the following three points to find the cause of the malfunction, repair, and system imp rovements are presented below.

(1) check the internal leakage of the boom cylinder. The easiest way is to move the arm raised, to see whether there is a significant drop in free. If the whereabouts of the obvious you remove the fuel tank to check the seals if worn should be replaced.

(2) Check the control valve. First of cleaning the relief valve, check the spool for wear, such as wear and tear should be replaced. The safety valve installation remains unchanged, and then check the wear of the manipulation of the valve spool to its clearance limit generally is 0.06mm serious wear and tear should be replaced.

(3) measuring the pressure of the hydraulic pump. If the pressure is low, then adjust the pressure to still tune up, then the severe wear of the hydraulic pump.

Check the measurement of the hydraulic pump pressure i s only 5-7MPa, significantly lower than the rated pressure of the hydraulic system. Found after the demolition of the hydraulic pump bushings are worn, the area of ??low pressure pump casing wall gear serious \"scan mode\", the sidewall has some wear and tear. Thus, causing the boom load the main reasons for not upgrading:

a. hydraulic pump serious wear and tear. Pump leakage at low speed; high-speed operation, the pump pressure increased slightly, but due to pump wear and leaks, the significant reduction in volumetric efficiency, it is difficult to achieve the rated pressure. Hydraulic pump to work long hours but also exacerbate the wear and temperature rise, the resulting wear of hydraulic components and seals of aging, damage, loss of sealing ability of hydraulic oil deterioration, and finally lead to failure.

b. Hydraulic component selection is u nreasonable. Boom cylinder size 70/40 non-standard series, the seal is also non-standard parts, the manufacturing costs are high and the seals to replace the inconvenience. Boom cylinder bore is bound to make the system a set pressure is high.

c. The hydraulic system design is unreasonable. Figure 1 shows the control valve and hydraulic steering gear is a single pump in series, the safety valve set pressure points 16MPa hydraulic pump rated pressure of 16MPa. Hydraulic pumps often work under full load or a long time overload (high pressure) and hydraulic impact, long-term oil, hydraulic oil contaminated, exacerbated by the hydraulic pump wear, so that the hydraulic pump pump shell burst ( such failure).

2 improvements and effect

(L) to improve the design of hydraulic systems. Finally, after many arguments, the priority valve with load sensing hydraulic steering gear the form shown in Figure 2. The new sy stem can request, in accordance with steering priority to assign the traffic, regardless of load size, level of steering wheel rotational speed can guarantee oil supply sufficient, the remaining part can supply all of the working device circuit, thereby eliminating the excess caused by power steering circuit oil losses and improve system efficiency, reducing the working pressure of the hydraulic pump.

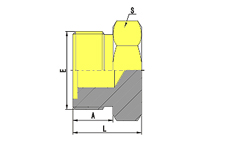

(2) optimize the design of the boom cylinder and hydraulic modeling, reducing the system working pressure. Using a standard line by optimizing the calculation of the boom cylinderorfs hydraulic fittings

Column 80/4. The hydraulic pump displacement is increased from 10ml / r to 14ml / r, the set pressure of 14MPa, to meet the lifting force of the boom cylinder and speed requirements.

(3) should also be noted that in the course of the proper use and mainten ance of the loader, add or replace the hydraulic oil on a regular basis, maintain the cleanliness of the hydraulic oil, and strengthen the routine inspection and maintenance.

Improve the hydraulic system, gear pump work more smoothly, no longer overload. Asphalt design is reasonable, to improve system efficiency, and give full play to the whole use of performance improve work efficiency. Smooth and reliable steering action to avoid the phenomenon of high speed to \"Gone with the Wind\".

没有评论:

发表评论