Web Design And Seo For www.china-webdesign.com

hydraulic ferrule - China Manufacturer

Thank you for inquiry my hydraulic ferrule, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/Ferrule/

, you should first check the quality of the seal surface, without flash, burrs, cracks, trimming. Defects such as pores and loose, the seal geometry and accuracy must meet the standards.

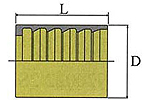

Hole using a combination of seals by the O-ring and wear ring (see Figure 1). Because of the O-ring is quite flexible, relatively easy to install; wear rings are less flexible, if installed directly on the piston of each step, the groove is easy to scratch the sealing surface, affecting the sealing effect. The installation of measures should be taken to ensure that the installation of the wear ring is not damaged. Wear rings made from filled PTFE (PTFE) materials, with corrosion-resistant characteristics, coefficient of thermal expansion, so the installation before 100 ° C the oil soak for 20min, and he gradually softened. be loaded the people piston in a trench and then tooling shown in Figure 2.stainless steel hydraulic hose fittings

Figure 2 shows the tooling by positioning sets and sets up. Positioning sets head the 5o chamfer for the guide O-ring and wear ring on the piston end of the trench. Sets up the good elasticity of 65 Mn stee l made of heat-treated, processed into a symmetrical eight structure. Should be noted that the processing valve hole in the bottom of the hour, minute to be uniform milling to open the valve should be saw cut alignment holes center to ensure that sets up each flap up open. The various parts should be (smooth) chamfer to avoid damage to the seal of the ring for each specification should have a set of corresponding tooling to ensure that their assembly requirements. After the installation is complete, does not allow the seals that are wrinkled, distorted, scratched, and installation of anti-phenomenon exists.braided hose fittings

Shown in Figure 3 for the cylinder of the hydraulic cylinder, the cylinder on a threaded Kong Changan row processing after the welding process, so that you will inevitably have to export in the threaded holes and the junction of the cylinder wall glitch . For the removal of the burr, must be designed to do special tools for processing, to achieve the purpose of smooth transition. Special structure of the tool shown in Figure 4. Use, the first Arbor from the threaded holes inserted from the side heads installed on the arbor on the rotating arbor can be glitches to get rid of and process a smooth surface. The other seal is a Y-shaped seals of polyurethane materials because of their high hardness, high flexibility, oil resistance, wear resistance and low temperature, it is widely used in the hydraulic cylinder. Its inner and outer lip shaft or hole with contour shape can be made to play the role of sealing and self-protection. High lip Y-ring, the short lip in contact with the sealing surface, the sliding friction is small, good wear resistance, long life; long lip and non-relative movement of the surface of large pre-compression, the work is not easy to traverse.

The high hardness of the Y-shaped ring of polyurethane materials, pre-compressed volume, often resulting in the installation, replacement seals squeezed broken, rolled and undercut other damage phenomena, and thus not achieve the desired sealing effect, and even failure. Assembly with a screwdriver to the sealing lip inside pressure along the bore; the outer lip of the ring or with a fine wire tied tight, so the outside diameter less than the cylinder inner diameter, and then the ring to give as gifts to the cylinder, and then thin wire out. But the two loading method is easy to scratch ring, leading to seal failure, increased maintenance time. In view of this situation, we use 0. lmm thick cold-rolled strip or copper cut into a rectangle, its length is equal to the Y-ring outer diameter of the circumference, and then use it to ring to bind tightly, and then little by little, give it away in the hydraulic cylinde r cylinder into the cylinder and the outer lip all out before the installation better

没有评论:

发表评论