Deduction of operating Tutorials

1 sample with a ruler to measure the length of the hose

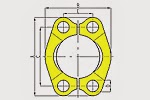

2 metal joints using a caliper measurement data , the sample was observed inside diameter hose

3 Prepare hoses and fittings needed

4 with a cutting hydraulic hose ends to cut the required length of the hose , the hose bore cleaning

5 skiving machine with outer rubber hose stripped , and then insert a metal hose connector sleeve.

Note: You must peel off the outer layer of rubber hose

6 straight pin plug connector metal hose directly to the bottom

7 . Measuring hose and hose samples are the same length

8 shrink tube with no taper reusable hose fittings

9 The transfer hose will be withheld by the provisions of the Data Locator quasi

10. Began to withhold hose, you can use the manual button or using the foot withhold withhold button

11 hose crimping in place , you can locate the alarm sounds , and then press the button to open the mold

12. Withhold withhold data caliper measurement is completed , using probes to detect

13 hose to the required data can be withheld

14 Withhold completed

parher wire braided hydraulic hose with power steering pump assembly is the main function of the work piece, the assembly consists of four parts assembly components.

2015年2月28日星期六

2015年2月24日星期二

Carrying the locator pull down, to avoid accidentally crashed

Carrying the locator pull down, to avoid accidentally crashed .

2 , in order to prolong the life of your jic hydraulic fittings , no accidents , we must add the original hydraulic oil.

3 , before each use , pay attention to the oil with a small brush to brush the nose cone front lubricants ( oil or hydraulic oil ) .

4, do not withhold rusted joints and pipes , to prevent impurities fall inside the nose .

Conservation Matters

1 , often moving surface injection mold base to wear lubricants.

2 , non- pressure pipe machine hours, please cover dust cover to prevent debris falling into the mold base .

3 , hydraulic oil tank over time specified by the manufacturer of hydraulic oil should be replaced , or the visual oil level gauge , if the hydraulic oil has been oxidized black bias must be replaced.

Hose crimping machine maintenance on the importance of this simple three-step , the most important thing is the staff to do a better pressure pipe reusablehydraulic fittings maintenance.

2 , in order to prolong the life of your jic hydraulic fittings , no accidents , we must add the original hydraulic oil.

3 , before each use , pay attention to the oil with a small brush to brush the nose cone front lubricants ( oil or hydraulic oil ) .

4, do not withhold rusted joints and pipes , to prevent impurities fall inside the nose .

Conservation Matters

1 , often moving surface injection mold base to wear lubricants.

2 , non- pressure pipe machine hours, please cover dust cover to prevent debris falling into the mold base .

3 , hydraulic oil tank over time specified by the manufacturer of hydraulic oil should be replaced , or the visual oil level gauge , if the hydraulic oil has been oxidized black bias must be replaced.

Hose crimping machine maintenance on the importance of this simple three-step , the most important thing is the staff to do a better pressure pipe reusablehydraulic fittings maintenance.

2015年2月20日星期五

On the use of hose crimping machine specification and maintenance measures

On the use of hose crimping wire braidedhydraulic hose specification and maintenance measures

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction .

Operating

1 , plus a full 46 # hydraulic oil 50kg ( preferably a genuine original oil ) .

2 , locators installation: first locator inserted in front of the nose ( Note : Locator can be directly inserted into the nose ) , the other end plugs in the electrical control box inside the corresponding socket.

3 , connect the power , if you are using a three-phase motor , be careful not to pick inversion (top : a motor fan clockwise direction is forward ) .

4, after the completion of the above steps , you can turn the pressure test .

5 , the use of locator : spin down more than a week each pressed into 1mm, every positive spin a grid of 0.01mm, and so on, the same size hose , fittings, metal fittings first reached the required pressure , no longer need to move Locator , has been finished to the specifications of the pressure , the result is fully consistent with data compression , when you complete the first root tubing pressure test , you have learned , and the remaining is gradually skilled.

Precautions

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction .

Operating

1 , plus a full 46 # hydraulic oil 50kg ( preferably a genuine original oil ) .

2 , locators installation: first locator inserted in front of the nose ( Note : Locator can be directly inserted into the nose ) , the other end plugs in the electrical control box inside the corresponding socket.

3 , connect the power , if you are using a three-phase motor , be careful not to pick inversion (top : a motor fan clockwise direction is forward ) .

4, after the completion of the above steps , you can turn the pressure test .

5 , the use of locator : spin down more than a week each pressed into 1mm, every positive spin a grid of 0.01mm, and so on, the same size hose , fittings, metal fittings first reached the required pressure , no longer need to move Locator , has been finished to the specifications of the pressure , the result is fully consistent with data compression , when you complete the first root tubing pressure test , you have learned , and the remaining is gradually skilled.

Precautions

2015年2月16日星期一

Hose crimping machine for permanent mechanical precision and life on the locking mechanism assembly

Hose crimping machine for permanent mechanical precision and life on the locking mechanism assembly, only selected high-quality steel materials, and the use of a unique heat treatment process. So hose crimping machine long life: the selection, heat treatment, hydraulic hosemachine process rationality and structure are inextricably linked.

Deduction of the machine tips, popularly known as crimping machine, crimping machine is a hydraulic hose fittings for withholding pipe assembly of hydraulic equipment, which will be the supporting metal fittings by deduction of the machine mold shrinkage force exerted by the hydraulic system the metal fittings on the firm withheld supporting hydraulic tubing and rubber hose.

1, dual hydraulic circuit principle of operation, that mouth and contraction movement of the piston back and forth and molds are relying on the power hydraulic power source. Not only does it move smoothly, return quickly, like a spring return, not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy withhold various shaped elbow.

2, the hydraulic system consists of motor, pump, valve, pressure regulator and hydraulic valve with dual hydraulic circuit retreat became a sport, but also in a dual hydraulic circuit from a rapid increase in the oil drain valve, in order to achieve a more rapid return purposes, and the speed is adjustable, noise and system pressure is reduced.

3, in the electrical control system, the control circuit applies PLC circuit, it is easy to repair the circuit, easy maintenance and replacement easy.

4, withhold mold and mold base accumulated error-free hose crimpingmachine process to ensure product after withhold withhold evenly spaced lines, no size head phenomenon.

5, in order to permanently withhold machine mechanical precision and life on the locking mechanism assembly, only selected high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life: the selection, heat treatment, machining process rationality and structure are inseparable!

Deduction of the machine tips, popularly known as crimping machine, crimping machine is a hydraulic hose fittings for withholding pipe assembly of hydraulic equipment, which will be the supporting metal fittings by deduction of the machine mold shrinkage force exerted by the hydraulic system the metal fittings on the firm withheld supporting hydraulic tubing and rubber hose.

1, dual hydraulic circuit principle of operation, that mouth and contraction movement of the piston back and forth and molds are relying on the power hydraulic power source. Not only does it move smoothly, return quickly, like a spring return, not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy withhold various shaped elbow.

2, the hydraulic system consists of motor, pump, valve, pressure regulator and hydraulic valve with dual hydraulic circuit retreat became a sport, but also in a dual hydraulic circuit from a rapid increase in the oil drain valve, in order to achieve a more rapid return purposes, and the speed is adjustable, noise and system pressure is reduced.

3, in the electrical control system, the control circuit applies PLC circuit, it is easy to repair the circuit, easy maintenance and replacement easy.

4, withhold mold and mold base accumulated error-free hose crimpingmachine process to ensure product after withhold withhold evenly spaced lines, no size head phenomenon.

5, in order to permanently withhold machine mechanical precision and life on the locking mechanism assembly, only selected high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life: the selection, heat treatment, machining process rationality and structure are inseparable!

2015年2月12日星期四

widely used , its advantages and technical performance as follows

widely used , its advantages and technical performance as follows :

1 , the operating principle of dual hydraulic circuit , i.e., mouth and contraction of the piston forward and backward movement of the mold and the motive power of the hydraulic power source is generated . Not only does it move smoothly , return quickly , like a spring return , not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy to withhold various shaped elbow.

2 , the hydraulic system by the motor , pump , solenoid valve , relief valve and the hydraulic valve would move back and forth with a double hydraulic circuit , but also in a double hydraulic circuit of a rapid increase in drain oil from the valve passage , in order to achieve more Quick return purposes, and the speed is adjustable , noise and system pressure is reduced.

3 , the electrical control system, the control circuit applies PLC circuit , it is easy to repair circuits , easy maintenance and replacement simple.

4 , mold and die holder withhold cumulative error -free bsp thread fittings process to ensure that the withholding of withholding product evenly spaced lines , no size head phenomenon .

5 , in order to withhold machine permanent mechanical precision and life on the locking mechanism assembly , not only chose the high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life : the selection, heat treatment, 60 Cone seal hose fitting process and the reasonableness of the structure are inseparable

1 , the operating principle of dual hydraulic circuit , i.e., mouth and contraction of the piston forward and backward movement of the mold and the motive power of the hydraulic power source is generated . Not only does it move smoothly , return quickly , like a spring return , not open and lock the mold phenomenon does not occur. And all around the cylinder locking system design through easy to withhold various shaped elbow.

2 , the hydraulic system by the motor , pump , solenoid valve , relief valve and the hydraulic valve would move back and forth with a double hydraulic circuit , but also in a double hydraulic circuit of a rapid increase in drain oil from the valve passage , in order to achieve more Quick return purposes, and the speed is adjustable , noise and system pressure is reduced.

3 , the electrical control system, the control circuit applies PLC circuit , it is easy to repair circuits , easy maintenance and replacement simple.

4 , mold and die holder withhold cumulative error -free bsp thread fittings process to ensure that the withholding of withholding product evenly spaced lines , no size head phenomenon .

5 , in order to withhold machine permanent mechanical precision and life on the locking mechanism assembly , not only chose the high-quality steel materials, and the use of a unique heat treatment process. So crimping machine long life : the selection, heat treatment, 60 Cone seal hose fitting process and the reasonableness of the structure are inseparable

2015年2月8日星期日

Over the years, the company is committed fittings and hose connector crimping machine

Over the years, the company is committed fittings and hose connector crimping machine ( reduction of the machine ) and research and development hose accessory products , is now supporting the establishment of partnerships in a number of hydraulic double connectory manufacturer. Companies believe our sincerity and faith put up a bridge , you and I work together to promote the enterprise efficient and harmonious development.

the technical performance hose crimping machine which

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction . Classification crimping machine , such as by using the function can be divided into hydraulic pressure pipe crimping machine , crimping machine brake pipe , air pipe crimping machine , crimping machine , etc. power tubes , such as by mechanical structure can be divided into straight -type crimping machine , double column withhold machine, crimping machine open type , C type crimping machine , such as by control can be divided into electromechanical crimping machine , PLC -style crimping machine , crimping machine CNC type , electro-mechanical crimping double hose connector which is widely used , its advantages and technical performance as follows

the technical performance hose crimping machine which

Hose crimping machine in our lives are often seen , but everyone 's understanding of the hose crimping machine is very strange, our technicians come under specific introduction . Classification crimping machine , such as by using the function can be divided into hydraulic pressure pipe crimping machine , crimping machine brake pipe , air pipe crimping machine , crimping machine , etc. power tubes , such as by mechanical structure can be divided into straight -type crimping machine , double column withhold machine, crimping machine open type , C type crimping machine , such as by control can be divided into electromechanical crimping machine , PLC -style crimping machine , crimping machine CNC type , electro-mechanical crimping double hose connector which is widely used , its advantages and technical performance as follows

2015年2月4日星期三

Cartridge - also known as the felling assembly

Cartridge - also known as the felling assembly, which consists of spool and sleeve, springs and seals four kinds of parts. Main function is used to control the direction of the main oil line, pressure and flow.

2 Control cover - from the cover of the embedded micro-pilot control element (throttling plug) as well as other parts and other accessories. It is mainly used to secure and guarantee Cartridge seal; communication control oil and felling the link between the control chamber and implement control.

3 pilot control 74 cone seal fitting on the control cover (also can be installed directly on the manifold body), is the implementation of action for felling Cartridge smaller gauge control valve. Mainly pain ¢ 10 ¢ 6 and the standard diameter solenoid valve, proportional valve, adjustable dampers, buffers, etc.. Felling larger size may need to use a smaller two-way cartridge valves for secondary control. Dimensions comply with ISO and national standards solenoid valve can be interchanged with the installation of similar products at home and abroad.

4 manifold blocks - used to install Cartridge, covers and other control valve control, communication and control circuit of the main oil blocks

2 Control cover - from the cover of the embedded micro-pilot control element (throttling plug) as well as other parts and other accessories. It is mainly used to secure and guarantee Cartridge seal; communication control oil and felling the link between the control chamber and implement control.

3 pilot control 74 cone seal fitting on the control cover (also can be installed directly on the manifold body), is the implementation of action for felling Cartridge smaller gauge control valve. Mainly pain ¢ 10 ¢ 6 and the standard diameter solenoid valve, proportional valve, adjustable dampers, buffers, etc.. Felling larger size may need to use a smaller two-way cartridge valves for secondary control. Dimensions comply with ISO and national standards solenoid valve can be interchanged with the installation of similar products at home and abroad.

4 manifold blocks - used to install Cartridge, covers and other control valve control, communication and control circuit of the main oil blocks

订阅:

博文 (Atom)