Web Design And Seo For www.china-webdesign.comThank you for inquiry my hydraulic machines, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/Hydraulic-Machine/

Auxiliary hydraulic system components, including the installation of the pipe and fittings, oil filter, oil cooler, seal, accumulator and instrumentation, etc. is good or bad can also seriously affect the normal operation of the hydraulic system does not allow the slightest negligence.

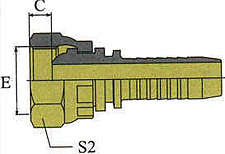

Design, it is necessary to consider the correct position of these auxiliary components configuration. Try to consider the use, ease of maintenance and adjustments, and pay attention to the neat appearance. The following highlights the installation of the tubing.hydraulic hose fitting

Piping installation quality impact to the oil spill, leak, vibration and noise, as well as the size of the pressure loss, and thus will have a variety of fault. The installation of the pipeline should be aware of the following:

(A) tubing length to fit. Construction gestures with wire bent into a desired shape, and then show decided to flowline length straight. Completely design often length may not be very accurate.

(B) satisfy the connection premise, the pipeline is as short as possible, avoid sharp turn, the corner positions as possible, in order to reduce the pressure loss.

(C) parallel and cross pipe spacing, at least 10mm to prevent mutual interference and vibration caused by the pipeline each other percussion grazing.hydraulic hose assemblies

(D) the tubing can be cold-formed (brass), bending (steel pipe) can also be used. Hot curved Bi tube pipe within the oxide should be removed.

(E) The suction pipe should be short, should be thicker, the the general suction nozzle are equipped with oil filter, oil filter must be at least in the oil below 200mm. Piston pump inlet pipe recommended nozzle mounted oil filter mouth, cut into the nozzle at a 45 ° bevel, helical faces toward the walls of the box, and so increase the flow area to reduce the flow rate and to prevent impurities from inhalation of oil pump.

(6) hydraulic system return pipe as far as possible away from the suction tube should be inserted under the oil tank, prevents back oil splash bubbles and quickly sucked into the pump. Return pipe nozzle should be cut to 45. Slant to expand the flow area to improve the flow of oil return status and prevent air anti-irrigation into the system.hydraulic ferrule

(G) relief valve oil return to the hot oil, should be kept away from the suction pipe, it can avoid the hot oil without cooling by pump suction system, causing the temperature rise.