Web Design And Seo For www.china-webdesign.com

hydraulic hose and fittings - China Manufacturer

Thank you for inquiry my hydraulic hose and fittings, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/

Hydraulic piping connections include: fittings to connect, JIC37 degree connector to connect the end of forming the connection (Walform), socket weld connections, welded connections and GS non-welded flange connected to the system.

The card connector - Pressure range: 250 - 800 Bar; applicable pipe size range: 4 - 42 mm; application materials: carbon steel and stainless steel.metric hydraulic hose fittings

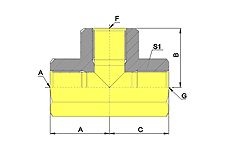

Card sets of pipe joints is composed of three parts: the connector body, ferrules, nuts. When the ferrule and nut sets on the pipe into the connector body and tighten the nut, the ferrule front lateral and the connector body cone fit evenly inside edge to bite into a seamless steel pipe to form an effective seal.

Advantages: wide range of applications mature; parts relatively low price; no special machine.

Disadvantages: only applies to the following 42mm of pipe connections; does not apply to the thin-walled tube; installation requires a large installation space and torque; does not apply to conditions of high security requirements; ca n not be used to strong vibration, shock, and pulse conditions.hydraulic hose sleeve

The JIC37 degree connector connection - Pressure range: 420 Bar (250 Bar, 100 Bar,); applicable pipe size range: 6 - 38 mm; applicable materials: carbon steel, stainless steel, brass, copper alloys, etc.

JIC37 degree connector consists of three parts: the connector body, bushings, and nuts. When the bushings and nuts into the steel pipe, flaring equipment in the steel tube end flaring shape, and then the connector body and the nut tightened, rigid conical contact surface seals and O-ring seal.

Advantages: widely used and mature; a wide range of applicable materials; easy to install; reusable disassembly.

Disadvantages: only applies to the following 38mm pipe connection; low nominal pressure (DNV standard excluded); does not apply to the thick-walled tube; need t he equipment end of the forming of the flaring.

The end of the molding connection (Walform) - Pressure range: 250 - 800 Bar; applicable pipe size range: 4 - 42 mm; applicable materials: carbon steel, stainless steel, copper alloy.

Walform connection fittings to connect alternative connections. Mother set into the steel pipe, steel tube end forming equipment in automatic extrusion load ring, then the connector body and the nut tightened by the rigidity of the connector body and the molding surface seal and ring seal.

Advantages: low torque and safety of the installation; the production process is quick and simple; advanced technology without leakage; reusable disassembly.

Disadvantages: only applies to the connection of pipe less than 42mm; forming end of the molding equipment.

Socket weld connection - Pressure range: 420 Bar (applies only to a small diameter); applicable pipe size range: 6 - 150 mm; application materials: carbon steel and stainless steel.

Socket weld connection pipe into the valve body welding, forming and threaded connection lookalike.

Advantages: wide range of applications; low component prices; advanced technology without leakage; low pressure system is a simple connection.

Drawback: the need for skilled welding workers; need welding equipment, good ventilation and fire prevention measures; require special cleaning and anti-corruption processing; will lead to environmental pollution.

Welded connection - Pressure range: 500 Bar (applies only to a small diameter); applicable pipe size range: 6 - 608 mm; application materials: carbon steel and stainless steel.

Welded flange connection and the connection of the welding head.

Advantages: wide range of applications; low component prices; advanced technology without leakage; pipe to pipe connection.

Drawback: the need for skilled welding workers; need welding equipment, good ventilation and fire prevention measures; require special cleaning and anti-corruption processing; will lead to environmental pollution.

6 GS non-welded flange connection - Pressure range: 690 Bar (420 Bar 350 Bar,, 210 Bar, 50 Bar ...); applicable pipe size range: 16 - 608 mm; application materials: carbon steel, galvanized steel, stainless steel , copper-nickel alloy, aluminum-copper alloy duplex stainless steel, super duplex stainless steel, titanium and so on.

GS non-welded flange connected to the system, including the GS to keep the ring flange connection system, the the GS37 degree of expansion port flange connection system and GS90 degree of flaring flange connection system.

Advantages: wide range of applicable materials; high cleanliness; easy low torque, less space for installation; leak connect ion; environmental protection.

Disadvantages: 1 \"below the pipe diameter to connect the lack of price competitive advantage; need the molding of the end of the flaring equipment

This is nice and great blog.A vimal Industrial system is an eminent company in the supply of Automation solutions for Assembly automation. With strong Engineering strength Vimal Industrial Solutions is a solution provider through basic concepts, designs, manufacturing, implementing and supporting Automated systems.Pipe end Forming machine

回复删除