Web Design And Seo For www.china-webdesign.com

hydraulic adaptors - China Manufacturer

Thank you for inquiry my hydraulic adaptors, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/Adapter/

Hydraulic equipment as shown in Figure 4-57, due to intermittent long time,

the implementation of components that require high-speed movement, so the

accumulator asbrass hose fittings

An auxiliary power source, used in conjunction with a smaller flow of the hydraulic

pump. When the manual valve in the median, the hydraulic cylinder stops moving,

liquidhydraulic tube fittings

Pump by one-way valve 2 to 4 fluid-filled accumulator when the accumulator to store

energy. When the accumulator pressure, opening to a setting value, unloading

Charge with the pilot outside the controlled sequence valve opens, the pump output

pressure oil through the valve back into the tank, pump 1 is in the unloading state.

When the valve 5

The left bit or right of access loop, pump and accumulator to the hydraulic cylinder

oil, so fast motion. Loop sequence valve

The set pressure is higher than the maximum working pressure of the system in order

to ensure that all traffic during the working stroke pump into the system.

1, there is the problem. Stops moving when the hydraulic cylinder, hydraulic pump

outlet pressure and high, low, can not be sustained unloading, causing the system

Power consumption, high oil temperature.

2, the problem analysis. When the valve 5 in the median, the hydraulic cylinder

stops moving, when the accumulator fluid-filled leaving the pressure setting value.

The hydraulic pump in the unloading state.

(1) If the Loop Road, a component or piping exists disclosure, will result in lower

oil pressure within the accumulator when the pressure is lowhydraulic fittings jic

3 sequence valve set pressure, valve 3 Turn off the hydraulic pump through valve 3-

unloading pathway is cut off, the hydraulic pump output fluid through one-way

Valve the Youxiang accumulator oil-filled, pressure is increased again. When the

accumulator pressure and 3 of the set pressure, the valve again so that the

hydraulic pump

In the unloading state. Loop, a component or piping leaks

(2) from the components themselves known by the principle of the structure of the

external control sequence valve, pressure oil from the accumulator from the outside

of the sequence valve control port

By the main valve spool cavity, the main valve spool orifice into the cavity.

When the pressure reaches the set pressure of the pilot valve spool is closed.

When the pressure reaches the set pressure, the pilot valve spool to open the main

valve spool opens. At this time, the hydraulic pump output fluid through the main

valve to open

Port back into the tank, hydraulic pump in the unloading state.

At the same time, pressur e oil from the accumulator continues to promote the pilot

valve spool and the valve vent hole and the hydraulic pump unloading oil confluence

Back into the tank, open to maintain the main valve spool.

When the oil pressure from the accumulator, and reduced the discharge of the estuary

of the pilot valve, pilot valve spool off, the main valve spool off

Unloading channel, the hydraulic pump is cut off, so the repeated opening and

closing of the above sequence valve. On the above analysis: the

The reason for the existence of a system problem is to select a pilot outside the

control sequence valve, unloading valve.

3 solution

Selection of alternative relief valve pilot operated unloading valve in the original

loop and valve 3 to form the growth rate of the accumulator circuit shown in Figure

4-58.

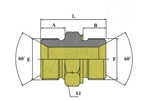

Pilot operated unloading valve, Pilot operated sequence val ve main difference is:

the pilot valve spool in addition by the spring 10 and the oil chamber 6 oil

Force, but also by the thrust of the plunger 7. The valve interface K, P, O,

respectively, connected to the accumulator, a hydraulic pump and tank.

Start oil-filled accumulator, unloading relief valve, pilot valve spool and the main

valve spool 12 in the closed position. Oil chamber in a and b

Equal to the pump outlet pressure, the plunger 7 at both ends of the balance of

power and the pilot valve spool does not produce thrust. With the increase of oil in

the accumulator

, Also increased the pressure in the oil chamber, a and b; overcome the spring force

when the pressure rises to a setting value, the fluid pressure in the oil chamber 6,

it will first

The pilot valve spool open, so the pressure oil from the mouth to P through the

orif ice 14, the pilot valve port, the center hole of the main valve 13, valve O port

flow back into the oil

Box. Fluid flow damping holes 14 so that the pressure in the hydraulic cylinder 6 is

less than the pump pressure, so the main valve port open, the hydraulic pump

unloading. This

6 cavity pressure when less than a cavity pressure, the plunger 7 would impose an

additional thrust to the pilot valve spool, prompting the pilot valve and main valve

of the valve port open

Larger, pump unloading more open. In this case, the absence of the pilot from the

accumulator to maintain the main valve to open stream

The amount of pressure in the accumulator leak decline, unloading relief valve is

also able to make the hydraulic pump in a continuous unloading state

.

没有评论:

发表评论