Web Design And Seo For www.china-webdesign.com

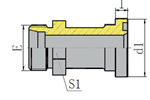

hose adapters - China Manufacturer

Thank you for inquiry my hose adapters, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/Adapter/

A. Form and taboos of the hydraulic drive system

Flow cycle the different ways the hydraulic drive system can be divided into two

kinds of open and closed.stainless steel hydraulic fittings

In open systems, hydraulic pump, oil absorption from the mailbox, for into the

implementation of the device, and then row back to the mailbox. Its simple

structure, good heat, oil1 pc fitting

The liquid within the tank to clarify, and thus the application is called universal.

Taboo: the open system, larger fuel tanks, air and fluid, more opportunities for

contact, it should avoid the infiltration of air.

In a closed system, the hydraulic pump into the tubing directly connected with the

implementation of the device drain line, forming a closed loop. To compensate for

system

Disclosure of losses, and thus often need to attached to a small auxiliary

compensation hydraulic pump and tank. Tank volume is small, compact structure; air

into the

Fewer opportunities into the oil is more stable; hydraulic pump can directly control

the flow direction, and allow the energy feedback.

Taboo: Closed system architecture is more complex, poor heat dissipation, ask for a

higher filtering accuracy, and generally avoid using.

Two. The main components of the hydraulic drive system

1) implementation of components (hydraulic cylinders, hydraulic motors).hydraulic pipe fittings

2) hydraulic pump.

3) control of regulatory elements. Including all kinds of pressure, flow and

directional control valves, to control and adjust the flow pressure, velocity, and

Direction to meet the performance requirements of the machine and various duty

cycle.

4) The auxiliary components. Such as fuel tanks, coolers, filters, accumulators,

pipe, pipe fittings, and control instrume nts and so on.

3. The advantages of the hydraulic drive

Electrical and mechanical transmission, hydraulic transmission has the following

advantages:

1) Similarly, power, hydraulic power units the weight is light, compact size, a

small inertia;

2) a large adjustment range stepless speed regulation;

3) smooth movement, to facilitate frequent and smooth commutation;

4) compatible with the electrical or compressed air, you can achieve a variety of

automation;

5) within the system, all institutions are working in oil, self-lubricating, can be

durable;

6) The hydraulic components are easy to achieve universal and standardized;

7) the hydraulic drive is easy to achieve overload protection.

In addition, when the power source failure, with the accumulator emergency action.

4. The disadvantage of the hydraulic dr ive

1) Leakage is difficult to avoid affecting the efficiency and smooth motion, and

does not apply to fixed higher than the transmission. In order to prevent

Only oil spills, with the pieces of the manufacture of high accuracy requirements.

2) the oil temperature and viscosity changes will affect the performance of the

drive mechanism. Hydraulic transfer in the low and high temperature conditions

Move have a greater difficulty.

3) liquid oil such as the infiltration of air, will produce noise and movement is

not smooth.

4) the manufacture of hydraulic components and system adjustments required to a

higher technical level.

5) determine the causes of failure and the elimination of these failures are more

difficult.

5 Design steps of the hydraulic drive system

In the design of the hydraulic drive system before, you shoul d fully understand the

process requirements of the machine, technical characteristics, to consider all

aspects of economic, technological and other

And whether the comparison should adopt hydraulic transmission, or which parts

should be used hydraulic transmission, and their degree of automation.

没有评论:

发表评论