Web Design And Seo For www.china-webdesign.com

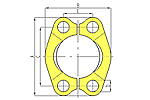

hydraulic flanges - China Manufacturer

Thank you for inquiry my hydraulic flanges, Tel : +86-0574-88461212, E-mail:ph@ph-fitting.com

http://www.ph-fitting.com/Flange-Fitting/

Control part of the design taboos

(1) to avoid the inappropriate choice of examples: the double-extraction steam

turbine hydraulic motor control system parameters in the control loop PID regulator hydraulic fittings jic

control

System parameters. Tuning properly, the pressure in the electric load, the exhaust

pressure, low pressure exhaust pressure three adjusting parameters in any one

subject

Disturbance will cause instability of the regulation system, caused by the reusable hose fitting

implementing agencies (steam turbine gate) shaking. K value is too large, will be

out

Now such as amplitude vibration or divergent vibration, resulting in high, medium

and low pressure hydraulic motor shaking; if the integration time T is small,

although the consumer

Addition to static deviation fast, but also may regulate the process of oscillation,

causing the shaking of the hydraulic motor, causing the electrical, thermal load

fluctuations

< br />. Therefore, a reasonable choice of the PID regulator of the value of K and T values stainless steel hydraulic fittings

​​are very important to the stability and sensitivity of the regulatory system.

Through on-site

Repeated testing and tuning, the power control loop, the pressure of the exhaust

pressure loop, the proportion of low-pressure exhaust pressure loop PID regulator

The coefficient of music re-select. Parameter settings, power, pressure exhaust

pressure, low pressure exhaust pressure in the unit operation order

Jump disturbance test, the positive stability of the system and over-the process of

good quality, and eliminates the hydraulic motor shaking phenomenon.

(2) to avoid a control logic failure

1) gives the control logic signal is inconsistent with the actual solenoi d valve

action, state and pre-set way of the servo system is inconsistent, may be the

original

Because the wiring is incorrect or garbled.

2) shows the control logic signal, while the actual solenoid valve action

inconsistent possible causes electrical disconnection or solenoid valve stuck, the

whole

The servo system is not working.

Instance: of CVC move, the state of the solenoid valve error, caused by the pilot-

operated check valve is blocked, the hydraulic cylinder at both ends of pressure is

essentially the same, the hydraulic cylinder

Do not move. CVC mobile emergency disconnect when the solenoid valve state error,

the hydraulic cylinder at both ends of the pressure change.

(3) to avoid the drive current of the servo valve is too large CVC tie-hydraulic

hydraulic servo system, servo valve drive current is too large, the hydraulic

cylinder leak.

(4) to avoid the thermal control signal failure of thermal control signal failure,

leading to the hydraulic motor off is not in place, causing the valve swing.

(5) to avoid feedback system dead zone is too large feedback system dead zone is too

large, resulting in adjust phenomenon. Delay of the feedback system to the governor

Always in the regulating state, causing the servomotor tic phenomenon.

Taboo: the multi-cylinder is not synchronized CVC rolling mill hydraulic servo

system, CVC hydraulic control system consists of four independent and identical

hydraulic position servo

Systems are in control, working under the Kun, axial movement in the opposite

direction. Four position settings, four hydraulic cylinders move the position

The absolute quantity of each other as a reference for fault diagnosis. At the same

time , consider the system response and customer service interference, the use of the

time period T letter

Smoothing filter, when the two position sensors location of the same Kun difference

is greater than 5mm, must have a hydraulic position servo system

There is a fault, combined with the state of the servo system can be to locate the

fault. When on, the location of two Kun difference is greater than 2mm, the same can

be

Can two sets of hydraulic position control system in the Kun Kun, a displacement of

the trend of the deviation, replacement of positioning. In general, the trend

The potential rapid changes of control are more likely to be defective.

(6) to avoid the feedback device failure instance: dual exhaust turbine hydraulic

motor, low pressure hydraulic motor position feedback value of a substantial wave of

Move, the unit of electric load an d pressure exhaust pressure also occurred in

volatility, run an immediate exit (low pressure exhaust pressure) control

The system. Double pumping unit as long as the exhaust pressure "Rabbit,

electricity, heat load between the existence of implicated decoupling adjustment,

low pressure hydraulic motors

Intense oscillation will be caused by repeated changes of the pressure governor

valve to form within the disturbance. When you quit the low-pressure exhaust

pressure control

Low pressure rotating baffle fully open, low-pressure exhaust and electric power, in

the pressure pumping implicated decoupling between the exit, shaking hours. In this

regard, the mining

Main hydraulic pump export hydraulic table to take reinforcement bracket, LVDT

linear displacement sensor casing lower part of the installation of fixed pallets,

and to develop the set

Inspections, complex tight core rod and tube nut point of order to effectively avoid

the occurrence of similar failures.

In summary, the LVDT fault when the electro-hydraulic control system, hydraulic

system failure, failure of the power transmitter, and DEH adjustable parameters

Tuning improper factors, will cause electro-hydraulic control of the executive body

shaking, resulting in system instability. When these ask

When the title, should be analyzed depending on the circumstances, to take

appropriate measures to safeguard the safe operation of the unit.

(7) to avoid the sensor improper selection of

1) position sensor zero drift so that the position error is too large.

2) position control accuracy fail to meet requirements, such as a position sensor

measurement is greater than the limit bit, or two sensors of the same rolli ng Kun

Position

Set the ultra poor, or on the same side, the next the Kun position value

ultra-poor.

3) set for the given position signal of CVC hydraulic cylinder displacement not

in place.

(8) sensor installation taboo instance

Example 1: The linear displacement transducer LVDT feedback line connection plug off

the LVDT core rod fracture, two sensor frequency difference is too small can not

The sensor to work properly.

Example 2: For the LVDT, to regularly check the feedback line plug is loose or off,

can also be soldered directly to the lead canceled Air

Empty plug to improve reliability; by increasing the frequency difference of two

displacement sensors (such as from 50Hz to 100Hz) to reduce the two

The possibility of the sensor resonance.

Example 3: overhaul within the si gnal line is disconnected or the solder joints Weld

disengaged, or forget to plug in the signal line, and control of the zero of the

feedback circuit

The point is improperly adjusted, resulting in zero is too high causing the system

is no signal input, the servo valve pressure output.

The Example Step 1: Steam Turbine Valve jitter

A 125kW unit electro-hydraulic (EH) system uses high-pressure anti-fuel system,

hydraulic motors used to control the turbine inlet valve

The opening. The servo valve on the hydraulic motor to the turbine control system

(DEH), electrical signals into the servo valve spool valve displacement

By changing the hydraulic motor into the oil and drain oil, control the stroke

position of the hydraulic motor. Use to adjust the valve chattering.

Exclude the DEH control system failure, the failure of the servo card and valve

posit ion transmitter failure, to determine the jitter is due to the servo valve

Failure causes.

From the working principle of servo valve, servo valve shroud can not be completely

blocked corresponds to the EH pressure oil inlet and the pressure to return to the

oil drain

Will lead to the slide valve to do the right and left reciprocating motion, the

hydraulic motor continuously in the valve into the oil and drain two states regulate

along with

Jitter.

没有评论:

发表评论